SWING M delivery pump / Part 2 Overview, operation and service

Operation

5.12.8

Cleaning the pump

1

2

3

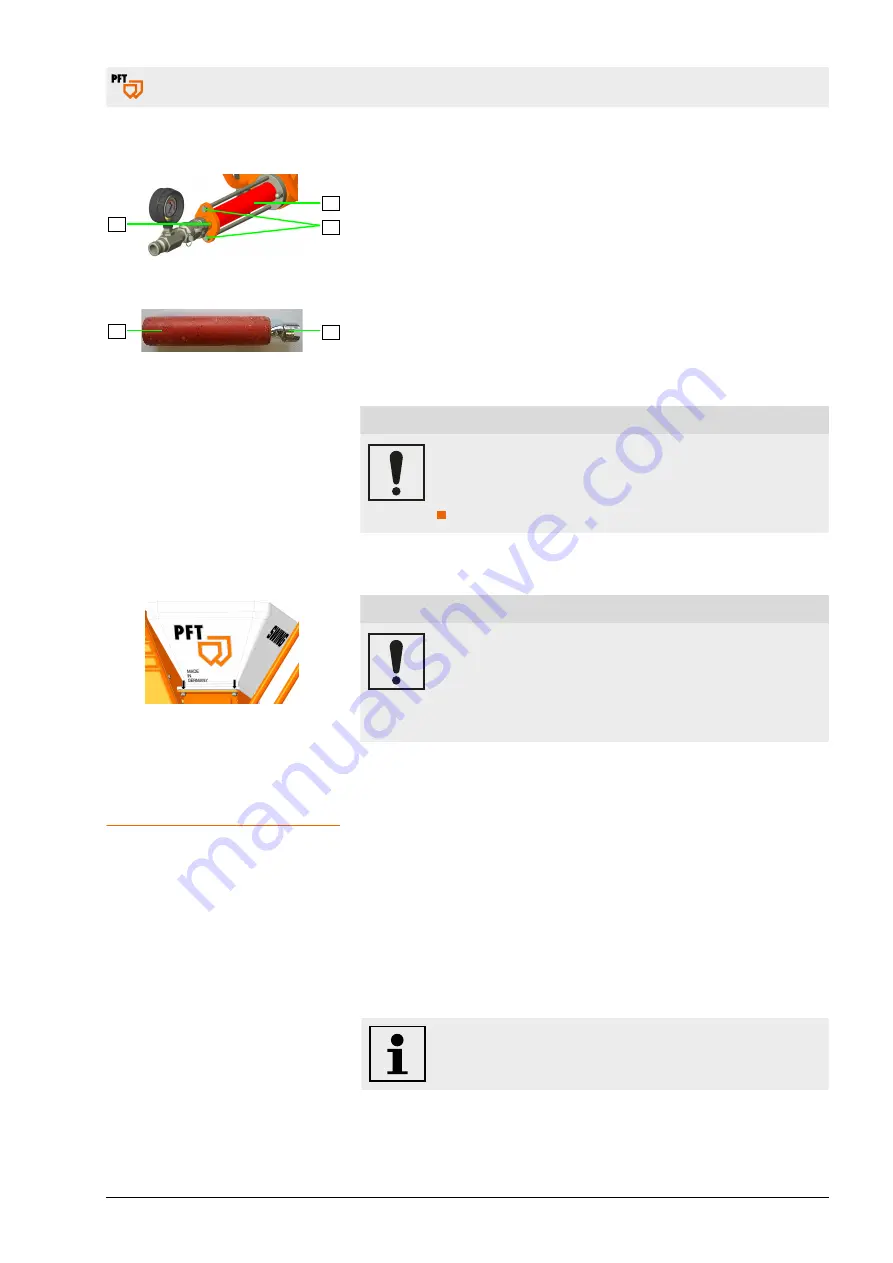

Figure 49: Loosening tie rod screws

4

5

Figure 50: Cleaning the pump unit

1. Slightly loosen the tie rod screws (1) so that any residual pressure

can escape completely.

2. Then loosen the tie rod screws (1) completely.

3. Remove and clean the pressure flange (2) with mortar pressure

gauge.

4. Remove the pump unit (3) and push the rotor (4) out of the stator

(5) and clean it.

5. Completely reassemble the pump unit (3).

6. Mount the pressure flange (2) and tighten the tie rod screws (1)

again.

NOTE

It is essential to spray the pump (rotor in stator) with

assembly spray before assembly, as otherwise the break-

away torque required for the pump motor is too high.

Assembly spray for PFT rotor/stator item no. 00588821

5.12.9

Tightening torques for the screws on the material hopper

Figure 51: Tightening torque

NOTE

If the material hopper is dismantled for cleaning and then

screwed back on, the tightening torque for the screws of

the material hopper must be observed.

Maximum tightening torque for the screws of the material

hopper is 15 Nm.

5.13

Reaction in the event of faults

Reaction in the event of faults

The following applies as a general rule:

1. In the event of faults presenting immediate danger to persons or

property, activate the emergency OFF function immediately.

2. Determine cause of the fault.

3. If the rectification of faults requires works in the danger zone,

switch off the system and secure against restarting.

4. Inform the manager on site immediately about the fault.

5. Depending on the type of fault, commission authorised skilled

personnel or rectify the fault yourself.

The following fault table gives information on who is

authorised to rectify the fault.

page 37 / 52