Mixing pump RITMO XL FC-230/400V / Part 2 Overview, operation and service

Operation

5.3.10.2 Putting the pressure booster pump into operation

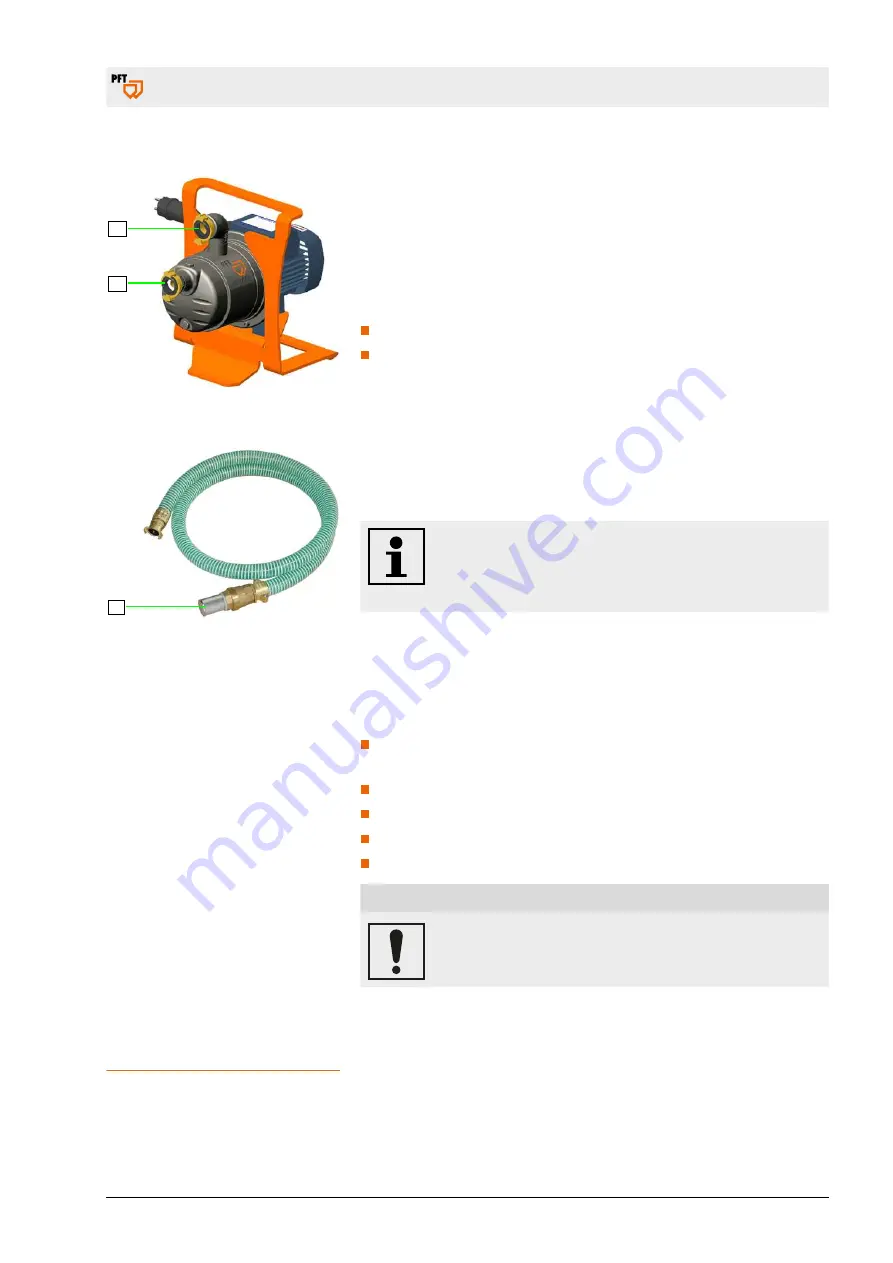

1

2

Figure 53: Connecting the pump

The following instructions have to be observed before operating the

pump.

The pump has to be installed in a horizontal position.

Before start-up both the suction line has to be connected to position 1

and the pressure line to position 2.

It is important that the lines are of adequate dimensions:

At least 1" for the suction line

At least ¾" for the pressure line

Make sure that the hose is completely airtight and immersed in the

liquid to be pumped, to avoid air being sucked in.

3

Figure 54: Suction strainer with filter

screen item no. 00136619

The end of the suction line (3) has to be equipped with a suction

strainer with filter screen and built-in non-return valve.

We recommend an additional filter for fine particles in the suction line.

The flow rate of the pump decreases with increasing

length of the suction line. Connect the booster pump as

close as possible to the water sampling point (pressure is

better than suction).

If all these points have been observed the pump can be switched on.

Depending on the length of the suction line, the suction time can be up

to a few seconds.

If the pump is still not delivering after a short time, this may have one

of the following causes:

There is still air in the pump and this has to be completely vented

again.

The suction line has a leak and the pump draws air.

The suction-side screen is clogged.

There is a kink in the suction hose.

The maximum suction head is exceeded.

NOTE

The booster pump must not run dry to avoid any damage!

5.4

Shutdown in case of emergency

Shutdown in case of emergency

In dangerous situations, machine movements have to be stopped as

quickly as possible, and the power supply has to be disconnected.

page 43 / 76