Mixing pump RITMO XL FC-230/400V / Part 2 Overview, operation and service

Maintenance

6.3

Maintenance plan

The following paragraphs describe the maintenance works required

for an optimal and trouble-free operation.

In the event that increased wear is detected during regular checks, the

required maintenance intervals have to be shortened according to the

actual signs of wear.

Should you have any queries regarding maintenance works and inter-

vals contact the manufacturer, see back page for service address.

The maintenance is limited to a few checks.

Thorough cleaning after use is the most important mainte-

nance.

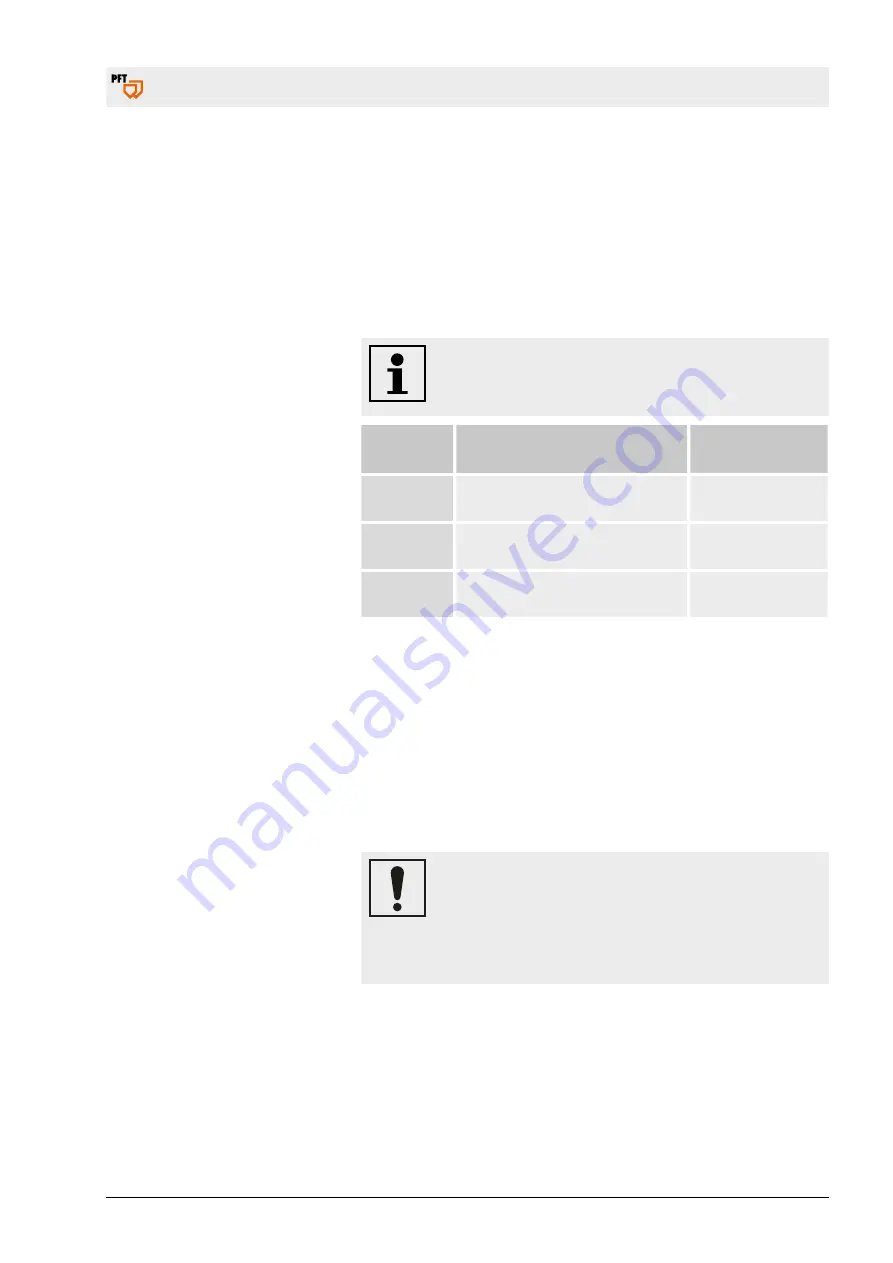

Interval

Maintenance work

To be carried out

by

Daily

Clean/renew the strainer screen

in the water inlet.

Operator

Monthly

Clean/replace filter of

compressor.

Service technician

Monthly

Clean/replace the strainer screen

in the pressure reducer.

Service technician

6.4

Maintenance work

In the event that increased wear is detected during regular checks, the

required maintenance intervals have to be shortened according to the

actual signs of wear.

Should you have any queries regarding maintenance works and inter-

vals contact the manufacturer, see back page for service address.

6.4.1

Implementation by a service technician

A service technician is responsible for the assembly and

commissioning of machines. In addition, service techni-

cians carry out maintenance and repair work. If work is

required on the control box or on other electrical parts,

the service technician must have completed vocational

training as an electrician.

page 67 / 76