Mixing pump G 4 X FU 230/400V / Part 2 Overview, operation and service

Operation

5.13

Ending work / cleaning the machine

5.13.1

Cleaning

Clean the machine daily at the end of work and in case of

extended breaks.

NOTE

Water can enter sensitive machine parts!

Before cleaning the machine cover all openings in

which no water must enter for safety and functional

reasons (e.g.: electric motors and control cabinets).

Remover the covers completely after cleaning.

5.13.2

Secure against restarting

WARNING

Danger to life from unauthorised restarting!

When working with the machine there is the risk that the

energy supply is switched on without authorisation. This

poses a danger to life for the persons in danger area.

Before starting work, switch off all electrical power

supplies and secure them against being switched back

on again.

If the protective covers are removed for cleaning

purposes, it is essential that they be properly reat-

tached when work is finished.

5.13.3

Emptying the mixing tube

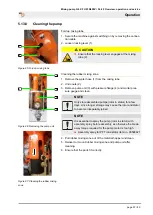

2

1

Figure 75: Switching off the star wheel

The machine must be cleaned daily after work and before prolonged

pauses:

1. Shortly before the end of work, switch the star wheel selector

switch (1) to the "0" position.

2. As soon as thinner material emerges from the spray gun, close the

air valve at the spray gun.

3. Turn the pump motor selector switch (2) to the "0" position.

4. Switch off the air compressor using the green toggle switch.

5. Open air tap on the spray gun.

WARNING

Danger of injury from discharged mortar!

Discharged mortar may lead to injuries to eyes and face.

Beware of residual pressure.

page 53 / 80

Summary of Contents for 00260621

Page 77: ...Mixing pump G 4 X FU 230 400V Part 2 Overview operation and service Disposal page 77 80...

Page 78: ...Mixing pump G 4 X FU 230 400V Part 2 Overview operation and service Disposal page 78 80...

Page 79: ...Mixing pump G 4 X FU 230 400V Part 2 Overview operation and service Disposal page 79 80...