Mixing pump G 4 X FU 230/400V / Part 2 Overview, operation and service

Operation

5.13.4

Disconnecting and cleaning the mortar hose

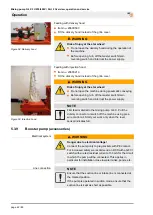

2

1

Figure 76: Disconnecting the water

hose

Disconnecting the water hose

1. Check the mortar pressure gauge (1) to determine whether the

mortar pressure has fallen to "0 bar".

WARNING

Overpressure on the machine!

When opening machine parts they can open in an uncon-

trolled manner and injure the operator.

Only open the machine if the pressure has fallen to 0

bar.

2. Loosen the cam lever (2) and decouple the mortar hose from the

mortar pressure gauge.

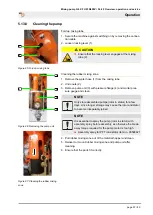

1

2

3

4

Figure 77: Cleaning the mortar hose

Cleaning the mortar hose

NOTE

The mortar hoses and spray gun must be cleaned imme-

diately at the end of work.

1. Connect the cleaner coupling (1) at the water extraction valve (2).

2. Press the water saturated sponge ball (3) into the mortar hose (4).

3. Connect mortar hose (4) with the sponge ball to the cleaner

coupling (1).

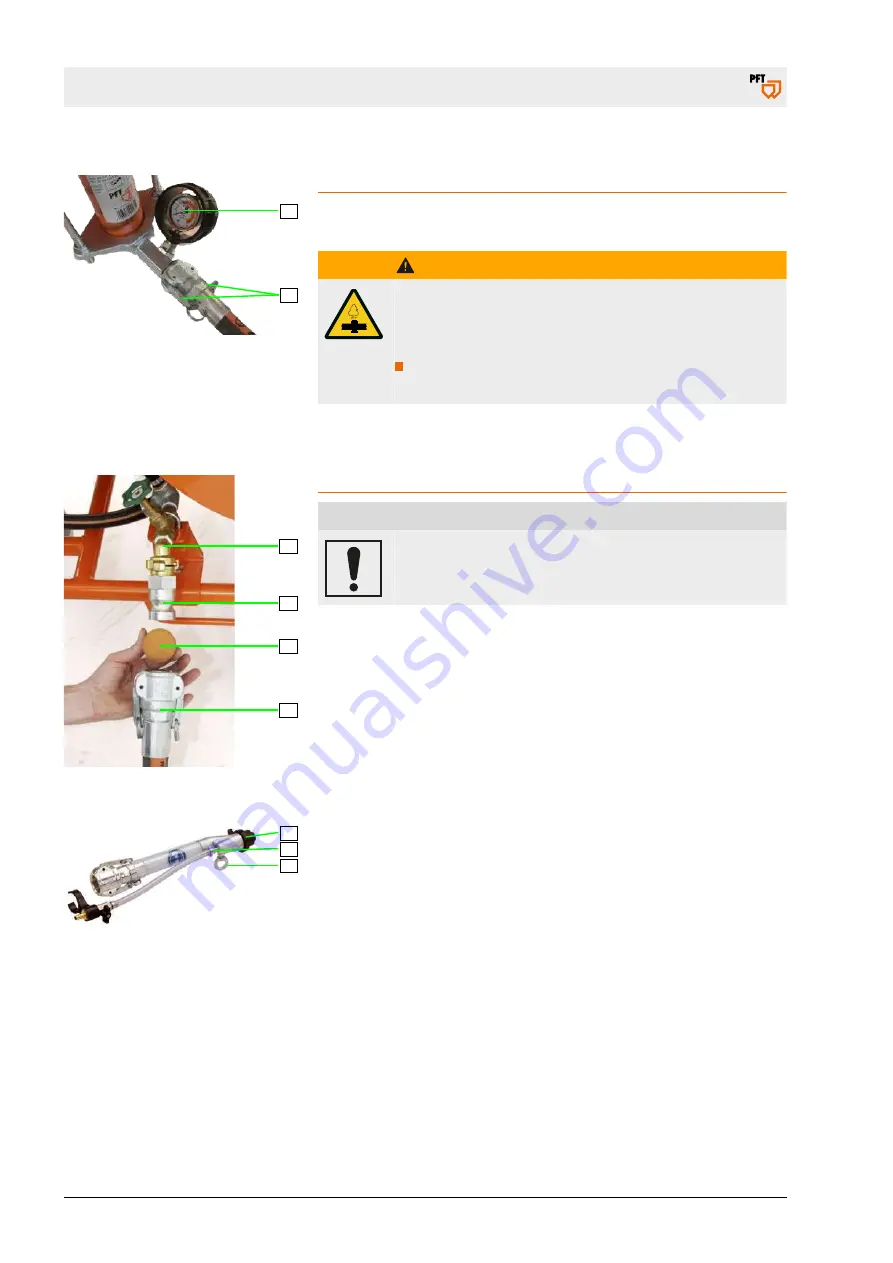

5

6

7

Figure 78: Cleaning the spray gun

4. Remove fine plaster nozzle (5) from the spray gun.

5. Undo eye bolt (6) and pull air nozzle tube (7) out of the spray head.

6. Open the water extraction valve until the sponge ball exits the

spray gun.

7. Repeat this procedure several times in case of heavy soiling.

8. For different hose diameters, the mortar hoses should be cleaned

separately with the appropriate sponge balls.

9. Hose down spray gun with water jet.

10.Knock free air nozzle tube (7) with mandrel.

11.Switch on compressor and blow air nozzle tube free.

12.Reassemble spray gun.

page 54 / 80

Summary of Contents for 00260621

Page 77: ...Mixing pump G 4 X FU 230 400V Part 2 Overview operation and service Disposal page 77 80...

Page 78: ...Mixing pump G 4 X FU 230 400V Part 2 Overview operation and service Disposal page 78 80...

Page 79: ...Mixing pump G 4 X FU 230 400V Part 2 Overview operation and service Disposal page 79 80...