Mixing pump G 4 X FU 230/400V / Part 2 Overview, operation and service

Operation

3

Figure 92: Detaching the coupling

NOTE

Clean mortar hoses immediately

3. Cover coupling connections with tear-proof film.

4. Release cam lever (3) and hose connections.

5. Remove blockage by tapping or shaking at the point of the

blockage.

6. If necessary, insert a flushing hose into the mortar hose and flush

out the mortar.

PFT flushing hose item no. 00113856

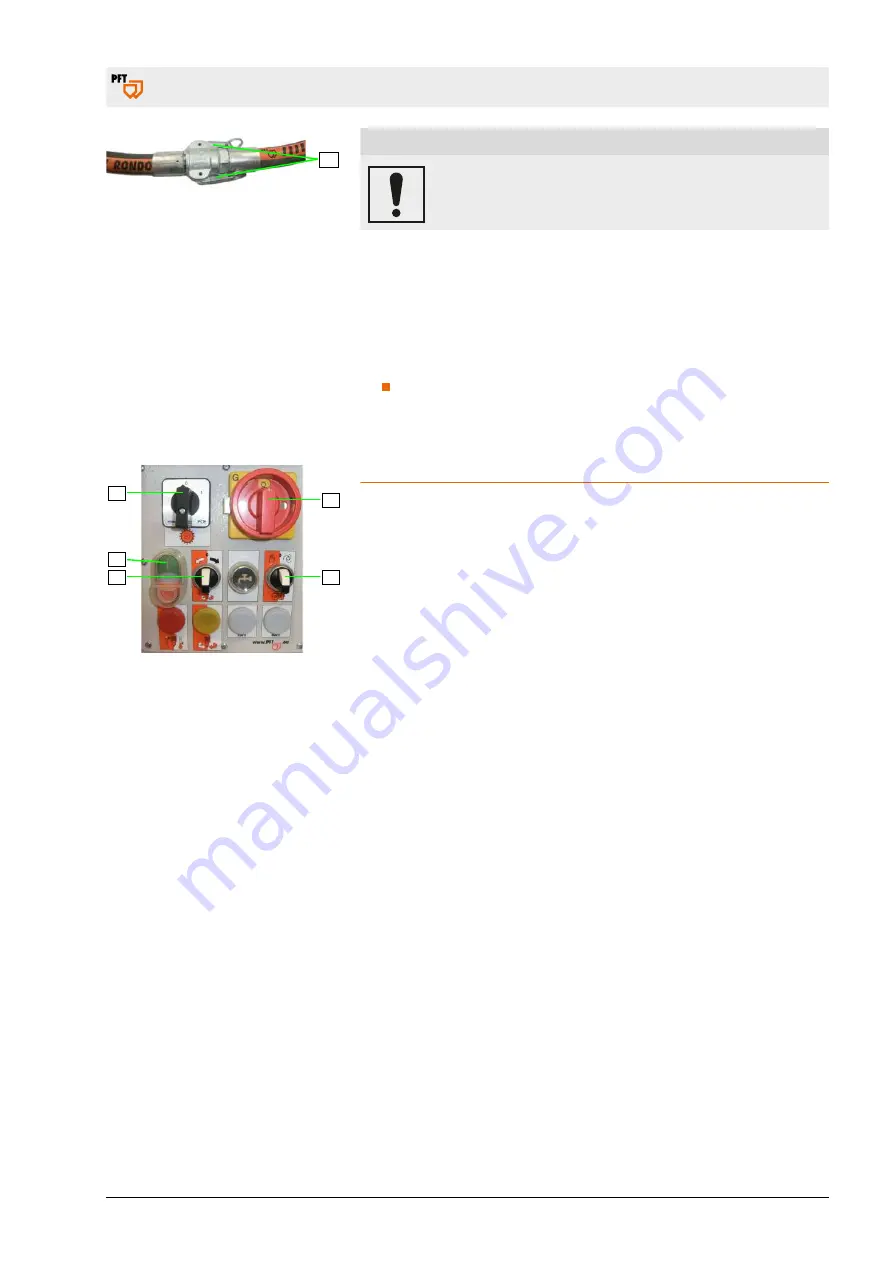

5.14.6.3 Switching on the machine after removing a blockage

3

1

4

2

5

Figure 93: Switching on the machine

again

Operation 230V

1. Turn the main reversing switch (1) to position "I".

2. Press the green pushbutton (2) control voltage "ON".

3. Switch on the air compressor using the green toggle switch.

4. Turn the booster pump selector switch (3) to the "AUTO" position.

5. Turn the star wheel selector switch (4) to the "1" position.

6. Turn the pump motor selector switch (5) to "right" position.

7. Let the machine run for a short while without mortar hoses.

8. As soon as material flows out of the pressure flange, switch the

pump motor selector switch (5) to the "0" position.

9. Apply wallpaper paste to the cleaned mortar hoses and connect to

the machine and spray gun.

10.Turn the pump motor selector switch (5) to "right" position.

11.The machine starts again as soon as the air tap at the spray gun is

re-opened.

page 65 / 80

Summary of Contents for 00260621

Page 77: ...Mixing pump G 4 X FU 230 400V Part 2 Overview operation and service Disposal page 77 80...

Page 78: ...Mixing pump G 4 X FU 230 400V Part 2 Overview operation and service Disposal page 78 80...

Page 79: ...Mixing pump G 4 X FU 230 400V Part 2 Overview operation and service Disposal page 79 80...