Mixing pump G 4 X FU 230/400V / Part 2 Overview, operation and service

Maintenance

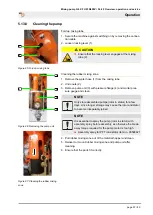

6.4.2

Air filter compressor

3

1

2

Figure 96: Cleaning the filter

Implementation by a service technician

1. Unscrew the covers (1 & 2).

2. Remove the filter frame (3).

3. Blow through the filter frame from the inside to the outside or tap it.

4. Replace the filter in case of heavy contamination.

5. Insert filter frame and screw on covers (1 & 2).

6.4.3

Plastic screen in the strainer

1

2

Figure 97: Plastic screen

Implementation by operator.

1. Remove the closure cap (1) from the strainer.

2. Take out the plastic screen (2) from the strainer (monthly).

3. Clean the screen.

4. Replace the screen if dirt is severe.

5. Refit the screen.

6. Replace the closure cap.

6.4.4

Strainer screen in pressure reducer

2

1

Figure 98: Strainer screen

Implementation by a service technician

1. Remove the closure cap (1) from the pressure reducer.

2. Take out the strainer screen (2) and clean (monthly).

3. Replace the strainer screen if dirt is severe.

4. Insert strainer screen and screw on the closure cap.

Screen for pressure reducer:

Item no. 20156000

page 70 / 80

Summary of Contents for 00260621

Page 77: ...Mixing pump G 4 X FU 230 400V Part 2 Overview operation and service Disposal page 77 80...

Page 78: ...Mixing pump G 4 X FU 230 400V Part 2 Overview operation and service Disposal page 78 80...

Page 79: ...Mixing pump G 4 X FU 230 400V Part 2 Overview operation and service Disposal page 79 80...