Container Mixing

Pump CMP 30 4.0

Part 2: Overview –

Operation – Spare Part Lists

Function description and operating sequence

20

2021-02-10

13 Function description and operating sequence

The machine combination

PFT CMP 30 4.0

is a continuously operating mixing and conveying pump for the

processing of plaster mortar. The machine is directly attached to a stationary silo with a 250 capacity outlet.

A horizontal continuous mixer mixes the ready-mixed dry mortar with water and transfers it to the storage

tank of the feed pump. The feed pump can variably pump 7-26 litres of mortar per minute into the mortar

hoses.

Due to the “open mixing pump system”, the consistency check can be carried out at any time after mixing

and not only at the end of the hose. The worm pump can also be retracted in order to fill mortar buckets,

for example.

The system is automatically controlled by an integrated switch cabinet in connection with the remote control

and the water supply.

The horizontal mixer, pump and water pump on the control box can be operated manually for starting up

the plant and also for cleaning at the end of work.

For a trouble-free operation of the system an appropriate water pressure is necessary. With the integrated

water pump it is also possible to feed water from a reservoir (water barrel) if there is not enough water.

If the water pressure is too low, the pressure switch built into the water supply automatically switches off

the

PFT CMP 30 4.0

to prevent malfunctions of the system.

13.1 Areas of application

The

PFT CMP 30 4.0

has been specially designed for the thermal insulation and composite system and

the entire plaster mortar sector. Due to the variable pump drive, e.g. adhesive and reinforcing mortar as

well as finishing or fine plaster can be optimally processed.

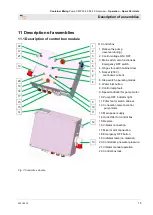

14 Basic equipment

The basic equipment of the mixing and pumping unit consists of the following assemblies, depending on

the construction site and application:

Frame CMP 30 4.0

Mixing tube with dosing and mixing shaft

Capacitive level probe

Control box

Water fitting CMP 30 4.0

Material container with pump

Pump shaft

Pressure flange with diaphragm seal and pressure gauge

Level probe KPS1

15 Safety regulations

Important!

When performing any work, observe the locally applicable safety regulations for mortar

conveying and spraying machines!