Container Mixing

Pump CMP 30 4.0

Part 2: Overview –

Operation – Spare Part Lists

Material

34

2021-02-10

26 Material

26.1 Flow characteristics

NOTE!

The pump unit R7-3S can be used with an operating pressure of up to 30 bar.

The minimum conveying distance depends mainly on how the material flows.

It is recommended to reduce the length of the mortar hose if you exceed an operating

pressure of 30 bar.

To avoid machine breakdowns and excessive wear on pump motor, mixing shaft and pump,

always use original PFT spare parts such as:

PFT rotors

PFT stators

PFT mixing shafts

PFT - Material hoses

These components are compatible with one another and form a single constructive unit

together with the machine.

Failure to follow these recommendations will result not only in the voiding of the warranty,

but the quality of the mortar you are producing will also suffer.

27 Mortar pressure gauge

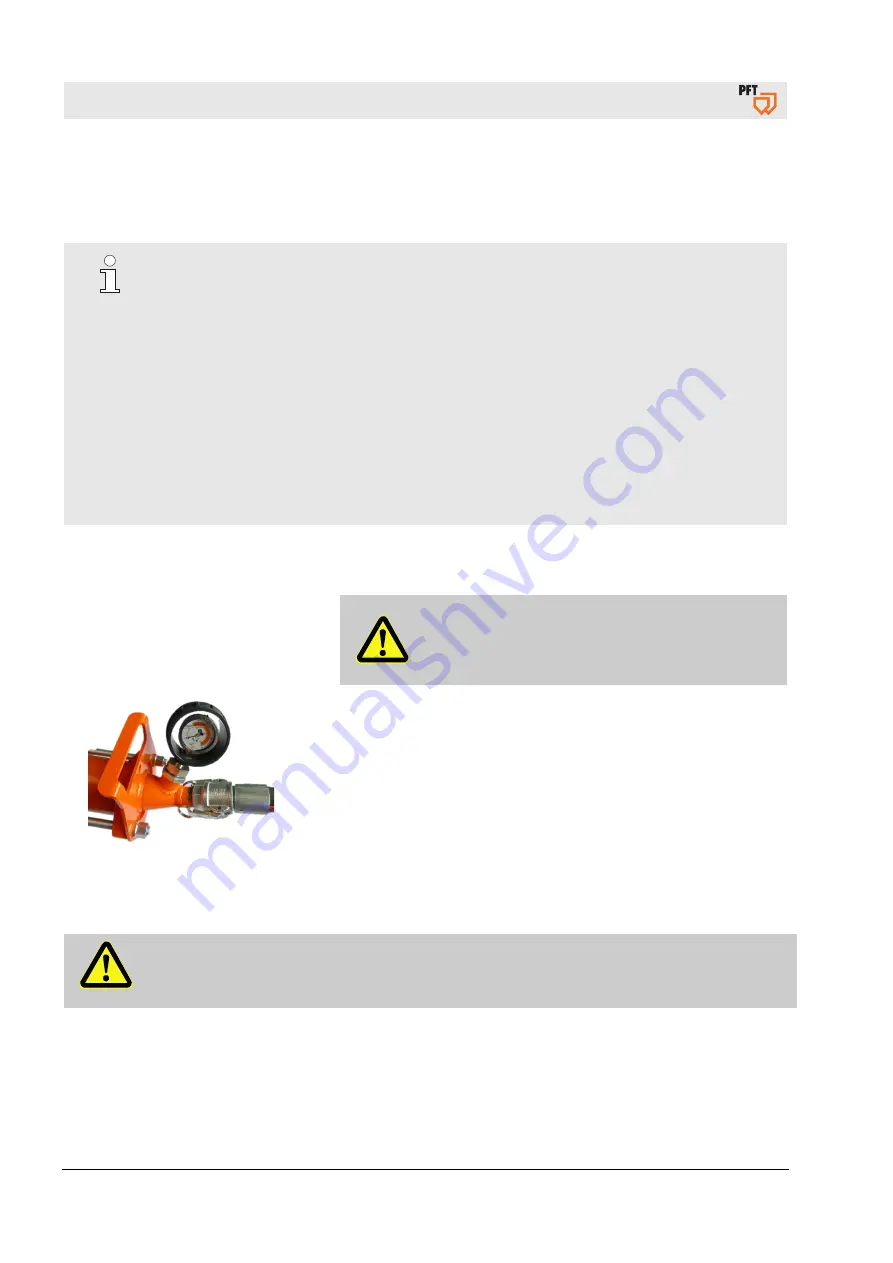

Important!

For reasons of safety, the use of a mortar pressure

gauge is recommended.

Fig. 34:

Mortar pressure gauge

PFT mortar pressure gauge

Benefits of the mortar pressure gauge:

Exact regulation of correct mortar consistency

Constant monitoring of correct conveying pressure.

Early detection of clogging or overloading of pump motor.

Produces zero pressure.

Contributes significantly to the safety of operating personnel.

Long lifespan for PFT pump components

28 Safety regulations

Important!

When performing any work, observe the locally applicable safety regulations for mortar

conveying and spraying machines!