Container Mixing

Pump CMP 30 4.0

Part 2: Overview –

Operation – Spare Part Lists

Applying mortar

2021-02-10

45

36.2 Opening the air tap on the spray gun

1

Fig. 67: Opening the air valve

1. Hold the spray gun in a bucket or tub to collect the wallpaper

paste that is in the mortar hose.

2. Open the air valve (1) on the spray gun.

3. As soon as mortar emerges from the spray gun,

close the air tap (1) again.

4. Dispose of wallpaper paste according to regulations.

5. Point the spray gun toward the wall to be plastered.

6. Check that no-one is in the mortar spraying range.

7. Open the air valve (1) on the spray gun.

8. The machine starts automatically via the pressure switch-off

and the material to be processed emerges.

NOTE!

The right mortar consistency is achieved if

the material on the sprayed surface merges

(we recommend applying material to wall surfaces

from top to bottom). Uniform mixing and spraying

cannot be ensured if the amount of water is

insufficient. This can clog the hoses and the pumping

components are then subjected to greater wear.

36.3 Interruption of work

NOTE!

Generally, the setting times of the materials to be

processed must be observed:

Clean the equipment and hoses as appropriate for

the setting time of the material and the length of the

interruption (take outdoor temperature into account).

Observe the guidelines of the material manufacturer

regarding interruptions.

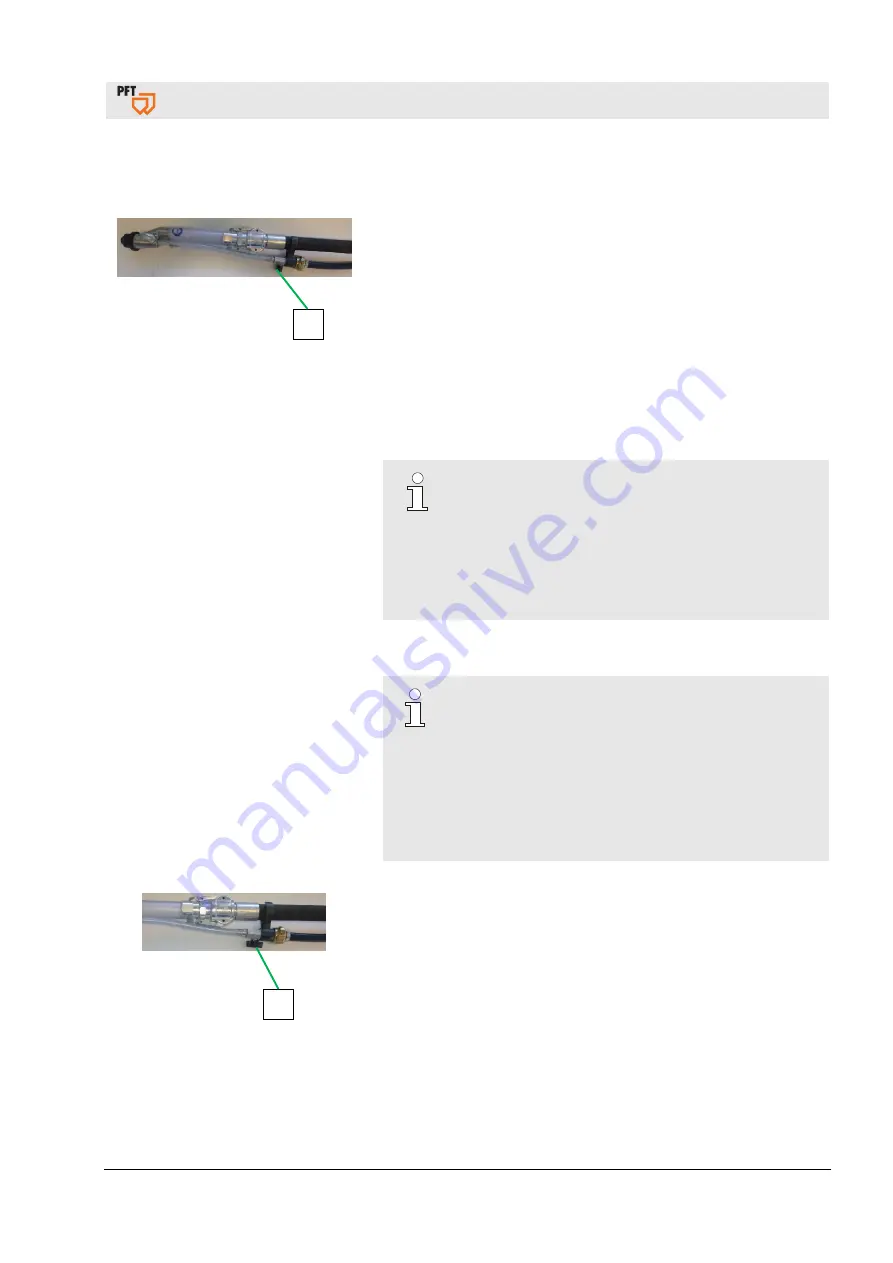

1

Fig. 68: Closing the air valve

1. For brief work interruptions, close the air valve (1).

2. The machine stops.

3. By opening the air valve (1), the machine will start running again.