Container Mixing

Pump CMP 30 4.0

Part 2: Overview –

Operation – Spare Part Lists

Troubleshooting

2021-02-10

51

41.4 Safety

Personal protective equipment

Wear the following protective equipment for all maintenance work:

Protective work clothing.

Protective goggle, protective gloves, safety shoes,

ear protection.

Personnel

Unless otherwise stated, the troubleshooting methods

detailed here can be carried out by the machine operator.

Some tasks may only be carried out by specialist personnel

or the manufacturer. These are specially indicated in

the description of the individual malfunctions.

Work on electrical systems must always only be carried out by

qualified electricians.

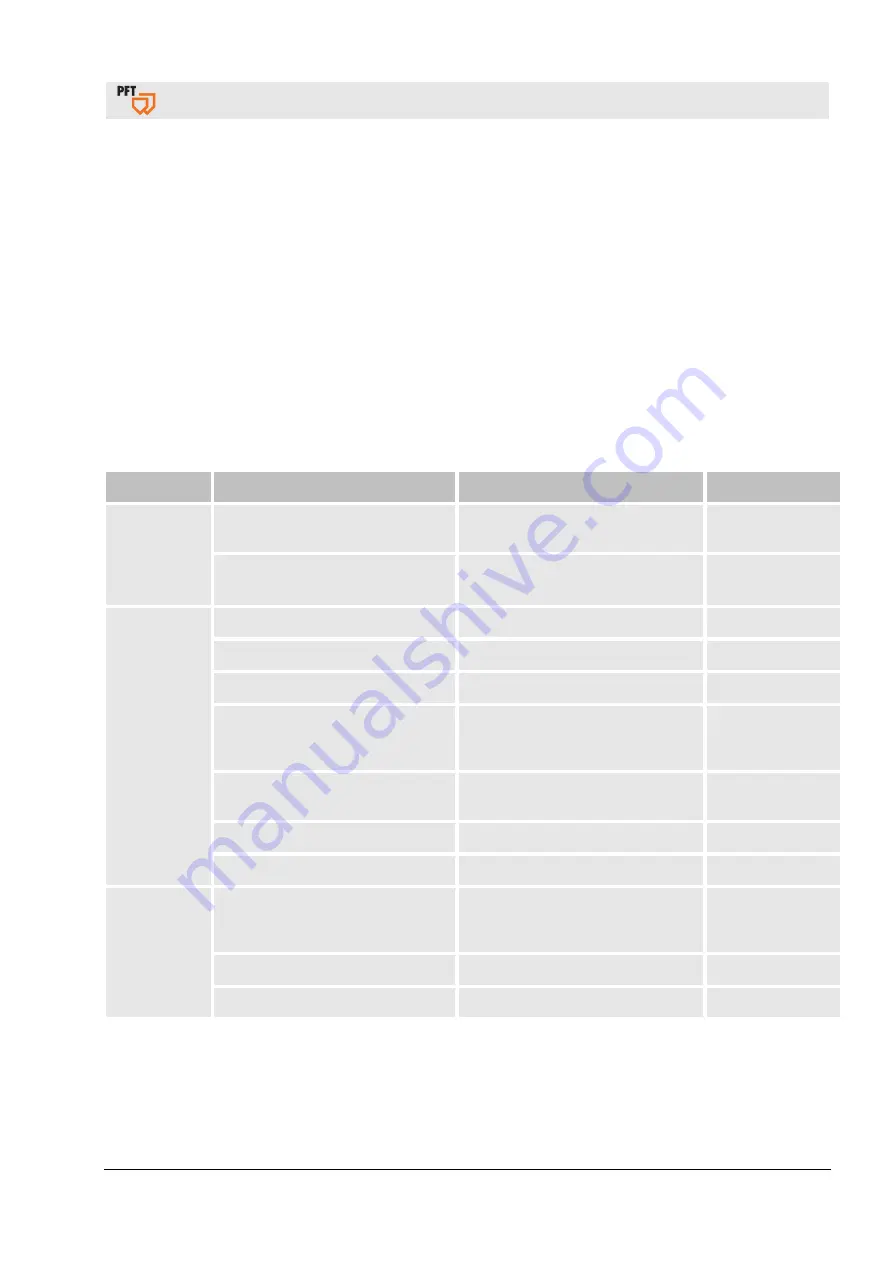

41.5 Table of malfunctions

Malfunction Possible cause

Solution

Performed by

Machine does

not start

Water

Water pressure too low

Check the water supply,

clean the dirt trap screens

Operator /

Service technician

Gauge displays pressure

below 2.2

bar

Check water pump

Service technician

Machine does

not start

Power

Power cable is defective

Repair the power cable

Service technician

Main switch not activated

Turn on the main switch

Operator

FI circuit breaker triggered

Reset the FI circuit breaker

Service technician

Control lamp yellow, fault Direction

of rotation lights up

Move the metal bar on the main

reversing switch in the opposite

direction

Operator

Motor protection switch triggered

Turn the motor protection switch to

the position “1” in the control box

Service technician

Operating button “ON” not pressed Press operating button “ON”

Operator

Contactor is defective

Replace the contactor

Service technician

Machine does

not start

Air

Insufficient pressure gradient in

remote control due to blocked air

line or air nozzle tube

Clean blocked air pipe or air

nozzle tube

Operator

Air safety switch incorrectly set

Adjust air safety switch

Service technician

Air compressor not activated

Switch on air compressor

Operator