Container Mixing

Pump CMP 30 4.0

Part 2: Overview –

Operation – Spare Part Lists

Clearing hose blockages

2021-02-10

55

42.1 Changing the direction of rotation of the mixing pump motor in case of

hose blockage

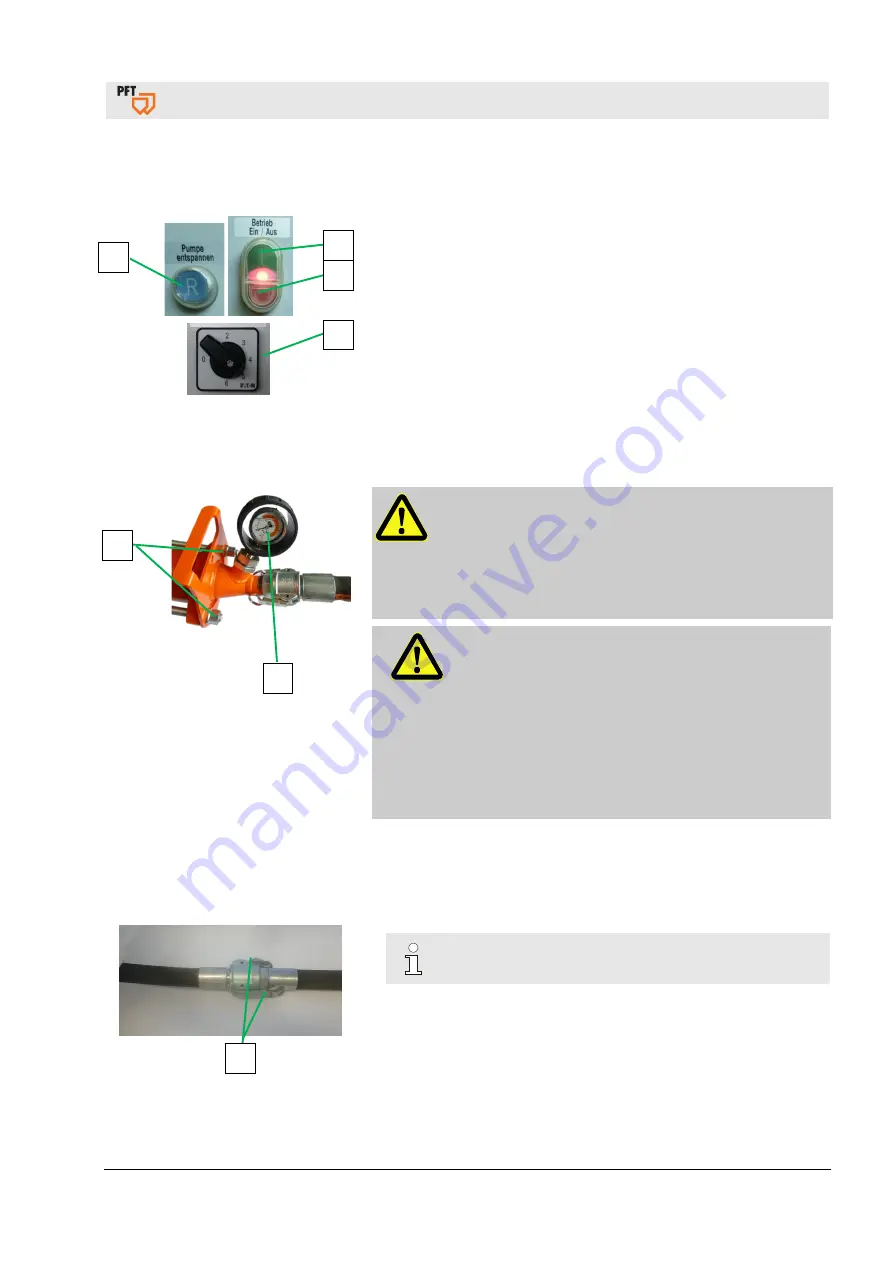

Fig. 83: Changing the direction of

rotation

1. Press the red pushbutton (1) to switch the control voltage “OFF”.

2. Turn the step switch (2) to position “5” Relieve pump.

3. Press the green pushbutton (3) to switch the control voltage “ON”.

4. Press the blue pushbutton (4) backwards until the pressure at

the mortar pressure gauge has dropped to “0” bar

42.2 Stopper will not come loose

1

Fig. 84: Mortar pressure gauge

DANGER!

Overpressure on the machine!

When opening machine components, these can fly open

in an uncontrolled manner and injure the operator.

Only open the mortar hoses if the mortar pressure

gauge (1) indicates the pressure has fallen to “0 bar”.

DANGER!

Danger of injury due to leaking mortar!

Escaping mortar can lead to injuries to the eyes

and face.

Always wear protective goggles.

Protective clothing, protective gloves,

safety shoes, ear protection.

Always position the machine so that you cannot

be hit should mortar escape.

1. Undo both nuts (2) on the pressure flange slightly to ensure

the residual pressure can escape.

2. As soon as the pressure has dropped to “0 bar”,

tighten the nuts (2) again.

3

Fig. 85: Detaching the coupling

NOTE!

Immediately clean the mortar hoses.

3. Cover coupling connections with tear-resistant film.

4. Release cam lever (3) and hose connections.

5. Remove blockage by tapping or shaking at the point of the blockage.

6. If necessary, introduce a flushing hose into the mortar hose and

flush out the material (PFT flushing hose Art. No. 00113856).

4

3

1

2

2