FERRO 100 II Part 2 Overview – Operation - Spare parts lists

Mortar manometer

30

2018-03-26

Fig. 36: Press button ON / OFF

NOTE!

Before switching over from step switch to other

operating modes, the control voltage must be

switched off through the push button operation “ON”

/ “OFF” (11). After the switchover of the step switch,

switch on the control voltage again via the push

button.

Fig. 37: Selector switch “Manual pump”

Turn the selector switch to position “4” (Manual pump).

Empty the pump container till a little residual water remains.

NOTE!

Never let the pump run dry as this reduces the

service life of the pump.

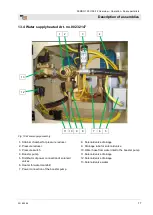

22 Mortar manometer

Fig. 38: Mortar manometer

DANGER!

Operating pressure too high!

Machine parts can open in an uncontrolled manner

and injure the operator.

Therefore:

– Do not operate the machine without mortar

pressure gauge.

– Use only mortar hoses with a permissible

operating pressure of at least 40 bar.

– The burst pressure of the mortar hose must

reach at least 2.5 times the value of the

operating pressure.

22.1

Connect material hose

1

2

Fig. 39: Connect material hose

Pour approximately two litres of lime sludge into the material hose.

Connect mortar hose (1) to the pressure flange (2).

Lay material hoses in large radius so that no kinks form in the

hoses.

Attach risers carefully in order to prevent them from tearing off

under their own weight.

DANGER!

Torn off hoses can beat about and injure

bystanders!

11

“ON”

“OFF”