FERRO 100 II Part 2 Overview – Operation - Spare parts lists

Mortar manometer

2018-03-26

31

Fig. 40: Mortar manometer

DANGER!

Never loosen the hose couplings as long as there is

pressure on the material hoses (check mortar

manometer)! The mix could burst out under

pressure and result in serious injuries, especially

injuries to the eyes.

Fig. 41:

Clean coupling connections

NOTE!

Ensure clean and correct connection of the

couplings!

NOTE!

The possible conveying distance depends mainly on

the flowability of the mortar. Heavy, sharp-grained

mortar has poor flow characteristics. Runny

materials have good flow characteristics.

If 25 bar operating pressure are exceeded the

mortar hose length must be reduced.

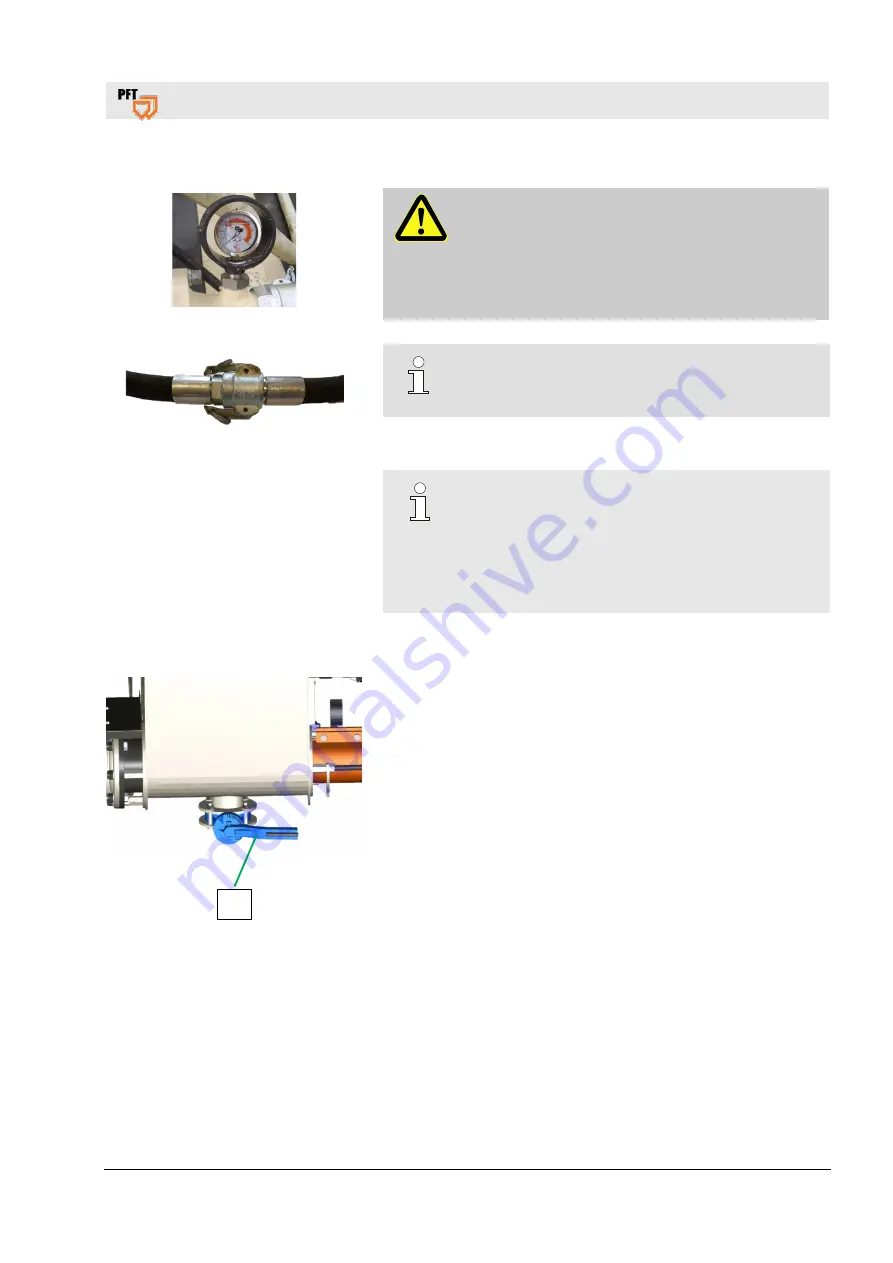

22.2

Drain water from pump container

1

Fig. 42: Open cleaning hole

Open cleaning hole and drain the residual water from the pump

container.

Only allow so much water into the pump container that the pump

does not run dry during the initial operation.