FERRO 100 II Part 2 Overview – Operation - Spare parts lists

Work on troubleshooting

38

2018-03-26

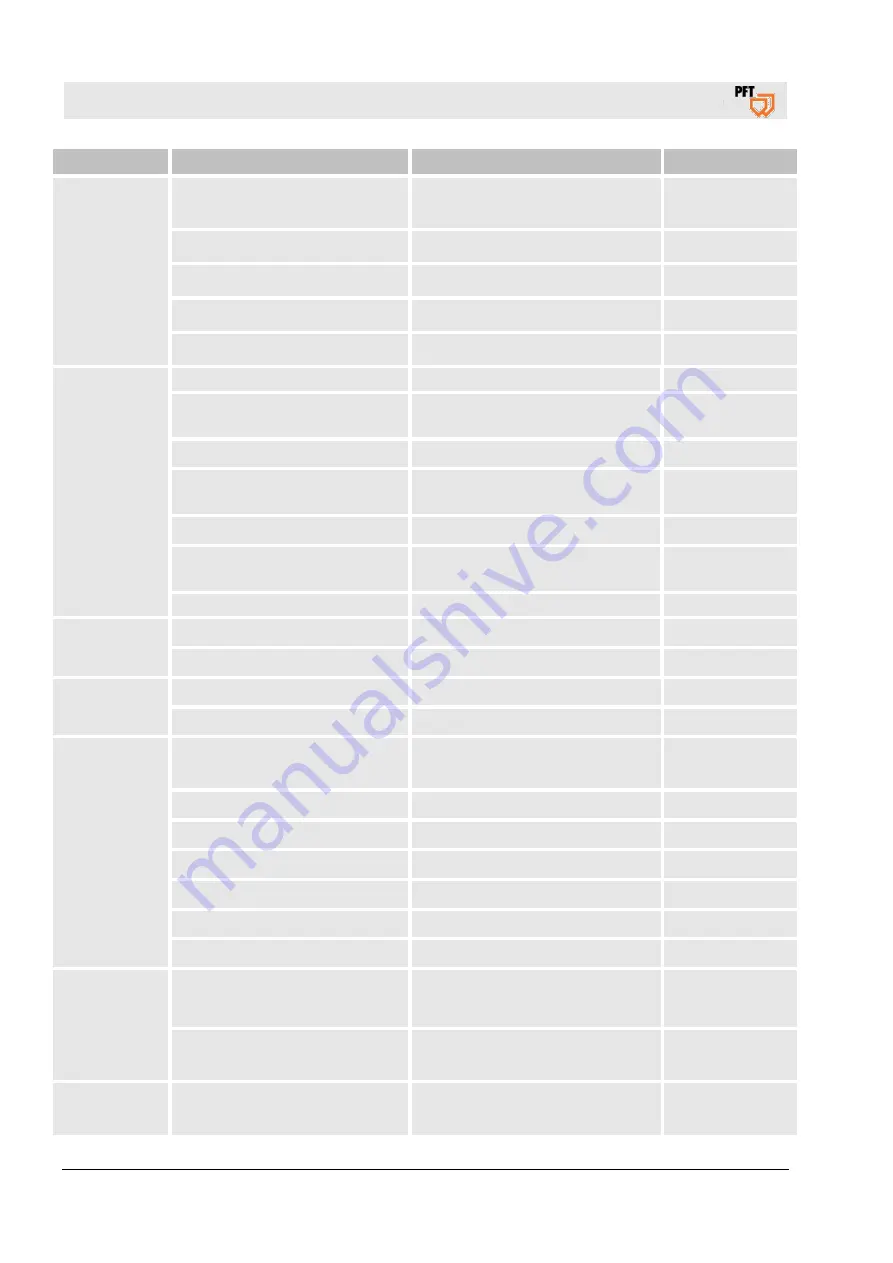

Fault

Possible cause

Troubleshooting

Rectification by

Water is not

flowing.

Flow meter

does not

display water

quantity.

Solenoid valve (hole in membrane

blocked)

Clean solenoid valve

Service engineer

Solenoid coil defective

Change solenoid coil

Service engineer

Pressure reducing valve closed

Open pressure reducing valve

Operator

Needle valve closed

Open needle valve

Operator

Cable to solenoid valve defective Replace cable to solenoid valve

Service engineer

Programme

does not start

Micro fuse on the transformer

Replace micro fuse

Service engineer

Level indicator, manual-0-

automatic switch faulty

Check parts and replace them if

necessary

Service engineer

Defective requirement

Check parts and replace them if

Service engineer

Manual/automatic selector switch

is on “manual”

Bring selector switch to the middle

position

Operator

Remote control drawn

Put on dummy connector

Operator

Conveyor line blocked

See Removal of blockages in the

hose

Operator

PLC-control program sequence

Check the programme sequence

Service engineer

Very less

material in the

machine

Material does not flow from the

Connect vibrating unit

Operator

Level sensor

Clean level sensor

Operator

Pump does not

start

Pump motor defective

Replace the pump motor

Service engineer

Connection cable defective

Change connection cable

Service engineer

Consistency

variation

“Thick-thin”

Water safety switch set incorrectly

or defective

Adjust or replace water safety

switch

Service engineer

Pressure reducer set incorrectly

Adjust pressure reducer

Service engineer

Rotor/stator is worn out

Replace rotor/stator

Service engineer

Clamp stretched too loosely

Retension clamp

Service engineer

KPS 1 sensor is contaminated

Cleaning sensor

Operator

Too little water

Water tank as intermediate buffer

Operator

Water inlet filter contaminated

Clean or replace filter

Operator

Mixer does not

start

Excessively pressed in / hardened

material in mixing tube

Open and clean mixing tube

Operator

Wet or hardened material in the

dosing zone

Open and clean dosing zone

Operator

Control lamp

red, fault lights

up

Overload due to the pump getting

blocked with dry material

Run the machine in backward

mode, remove pump and clean it

Operator