FERRO 100 II Part 2 Overview – Operation - Spare parts lists

Functional description – work flow

20

2018-03-26

15 Functional description – work flow

The machine combination PFT

FERRO 100 II

is a continuously working mixing and conveying pump for

processing floating screed.

Adhere to the usage directives of the material manufacturer.

The machine combination

PFT FERRO 100 II

is in use, ready for connection under a silo / container.

The material reaches in the collection tank of the conveying pump by a horizontal mixer equipped with its

own drive after addition of water in mixing tube and is forwarded from there at up to 120 l/min to processing

plant. The central control box with programmable logic control (PLC) regulates the interplay of the

components in the automatic mode.

For the run-in of the system and even the cleaning after finishing the work, all functions can also be

controlled manually at the control box.

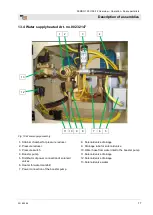

For a more secure functioning of the system, an appropriate water pressure is necessary. With the

integrated booster pump, even an external supply from a collection tank (water tank) is possible if the water

quantity is not adequate. The pressure switch built-in the water supply switches off the machine in the event

of very low pressure to avoid malfunctioning of the system.

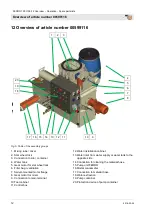

15.1

Basic equipment

Depending on the construction site and application, the basic equipment of the mixing and pump unit

consists of the following components:

Tool cabinet

Water installation cabinet

Control box FERRO 100 II

Star wheel lock with gear motor

Central body of FERRO 100 II with mixing tube and gear motor

Capacitive level sensor, dry material sensor

Pump container with pump shaft and gear motor

15.2

Safety rules

Caution!

Observe the regional safety rules for mortar conveyors and mortar guns!