FERRO 100 II Part 2 Overview – Operation - Spare parts lists

Maintenance

2018-03-26

47

Secure against restarting

DANGER!

Danger to life from unauthorised restarting!

When working with the tool, there is the risk that

the energy supply is switched on without

authorisation. This poses a danger to life for the

persons in danger area.

Therefore:

– Switch off all energy supplies before starting

any work and secure against restarting.

NOTE!

Maintenance of the FERRO II is limited to a few

checks. Thorough cleaning after use is the most

important maintenance.

Mixing tube / mixer / outlet / pump container /

pump:

Regular check on caking.

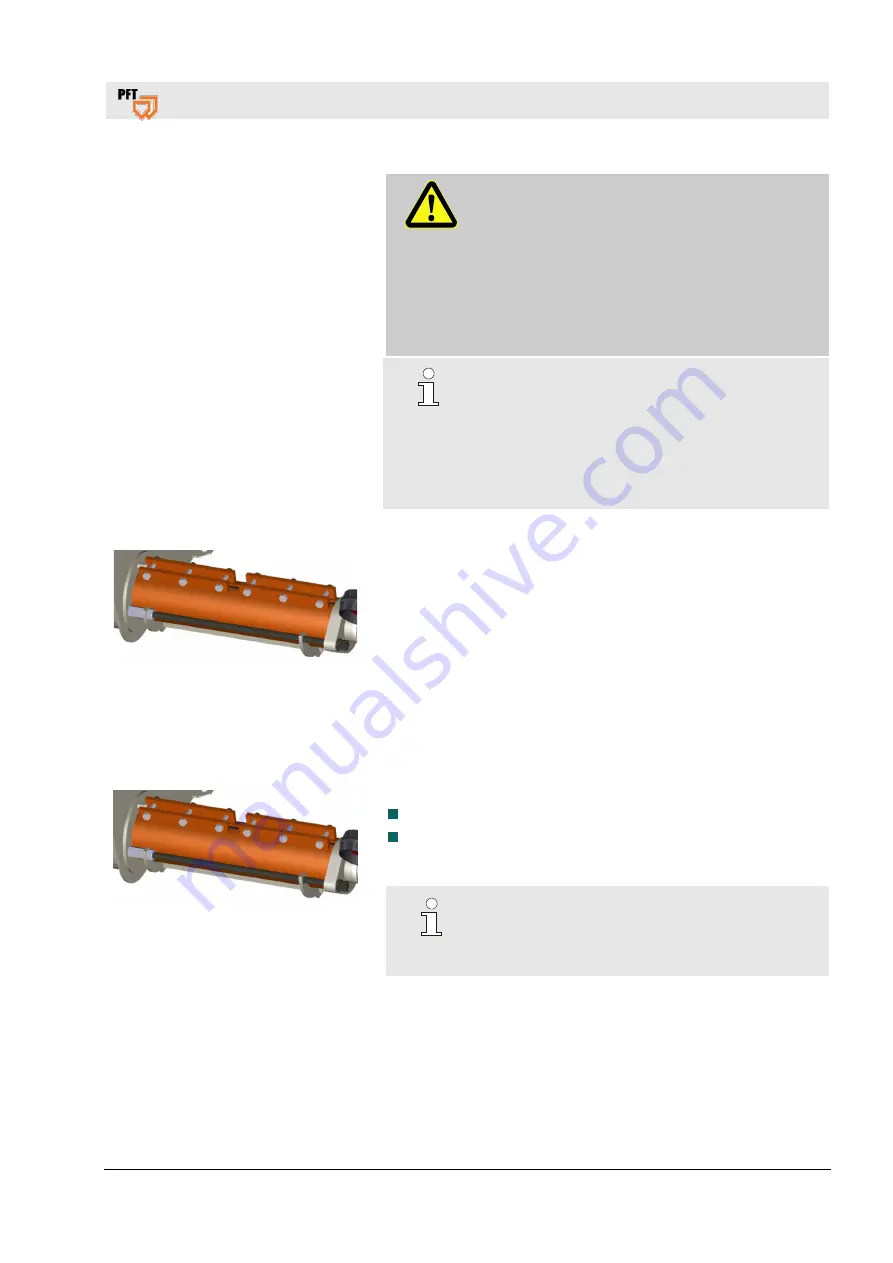

34.1

Adjust pump

Fig. 76:

Stator can be retightened

The FERRO II is equipped with a stator that can be retensioned.

If the pumping pressure decreases, the stator can be adjusted.

The supply pressure is approx. 20 – 25 bar.

Do not adjust the pump during operation.

The lesser the voltage of the spiral casing, the lesser is the wear

of the spiral pump.

34.2

Change pump

Fig. 77:

Change pump

Pump parts that do not achieve the required pumping pressure

when clamped, have to be replaced.

When changing the pump, it has to be ensured that:

all screws of the clamp are tightened uniformly.

the tie rod screws for rubber stators must not be tightened too

much and the sheath end in the flanges must be positioned

flush and centred.

NOTE!

Only store assembled pump (rotor in stator) for a

few days as rotor and stator can get connected

inseparably in case of prolonged storage.