____________________________________________________________________________________________________________

PFT G 5 c FU 230

12

Setting Values:

ATTENTION! technical modification

01.2005

____________________________________________________________________________________________________________

________________________________________________________________________________________

Knauf PFT GmbH & Co. KG

Telephone

09323 / 31-760

PO Box 60

Telefax

09323 / 31-770

D-97343 Iphofen

Internet

www.pft.de

________________________________________________________________________________________

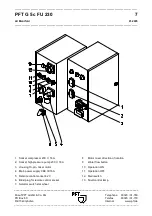

Safety switch

Switching on the machine

Switching off the machine

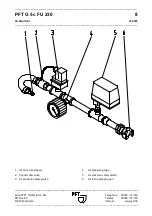

Water

2.2 bar

1.9 bar

Air

0.9 bar

1.2 bar

Compressor

2 bar

3 bar

Compressor safety valve

1.5 bar against closed air pipe (factory setting, secured)

Pressure reducing valve

1.9 bar for maximum flow at water manifold (1000 l/min)

Motor protection switch

Output

Setting value

Designation

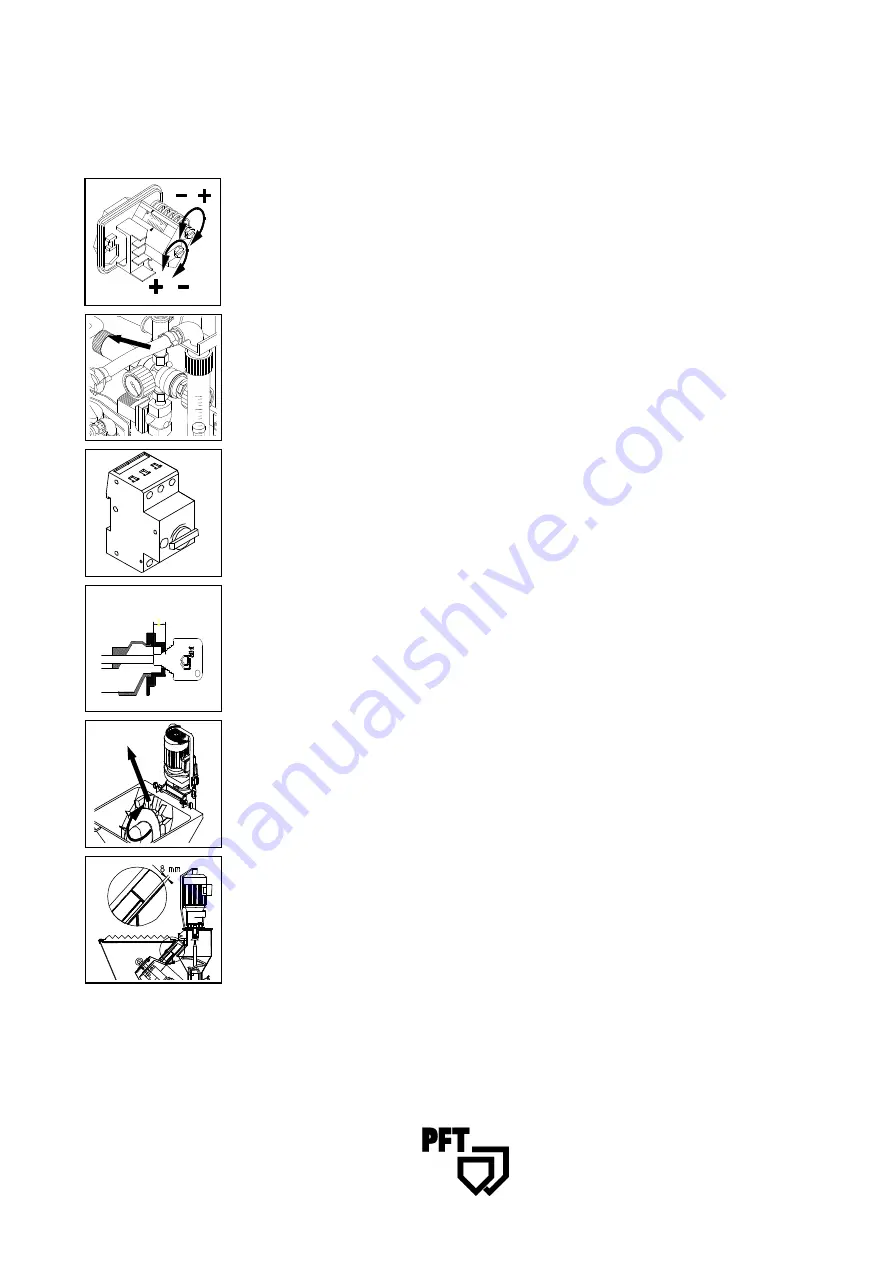

Star wheel

0.37 kW

1.6 A

Q2

Air nozzle tube gap

The gap between air nozzle tube and spray cap should always be equivalent to the

diameter of the spray cap;

e.g.: 14 mm spray cap = 14 mm gap.

Direction of rotation of the star wheel motor

The star wheel usually operates independent of the direction of rotation. If a SILOMAT

conveying system is being used, we recommend a clockwise direction of rotation

(factory setting). This ensures that the pump motor also runs in the correct direction.

Star wheel

Gap star wheel to hopper floor: Factory setting approx. 8 mm

Rule of thumb:

1.5 x diameter of largest dry mortar particle. If required, star wheel distance disk

(item no. 20 10 19 00) can be installed for coarse plaster.