____________________________________________________________________________________________________________

PFT G 5 c FU 230

13

Mortar Pump

01.2005

____________________________________________________________________________________________________________

________________________________________________________________________________________

Knauf PFT GmbH & Co. KG

Telephone

09323 / 31-760

PO Box 60

Telefax

09323 / 31-770

D-97343 Iphofen

Internet

www.pft.de

________________________________________________________________________________________

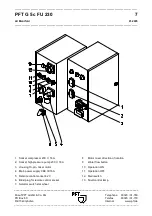

The PFT G 5 c mixing pump is standard-equipped with a D6-2L pump system.

Rotor and stator are subject to wear and must be inspected on a regular basis.

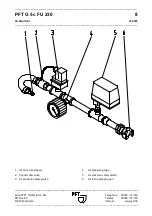

WARNING!

The use of a mortar pressure gauge is absolutely imperative according to the safety

regulations of the Builder’s Guild.

PFT mortar pressure gauges monitor the mortar consistency efficiently and easily.

Some advantages of the mortar pressure gauge:

-

Exact regulation of correct mortar consistency

-

Constant monitoring of correct conveying pressure

-

Early detection of clogging or overloading of pump motor

-

Early detection of clogging or overloading of pump motor

-

Establishes zero pressure

-

Contributes significantly to the safety of operating personnel

-

Durability of pump components

PFT pump components

New pump components with a conveying hose of 10 m should attain a conveying

pressure of approx. 15 bar / 30 bar and maintain a backpressure of approx. 8 bar /

12 bar before and after the first spraying. We recommend using the PFT pressure

tester with coupling and outlet tap to monitor the backpressure

(item no. 20 21 68 10).

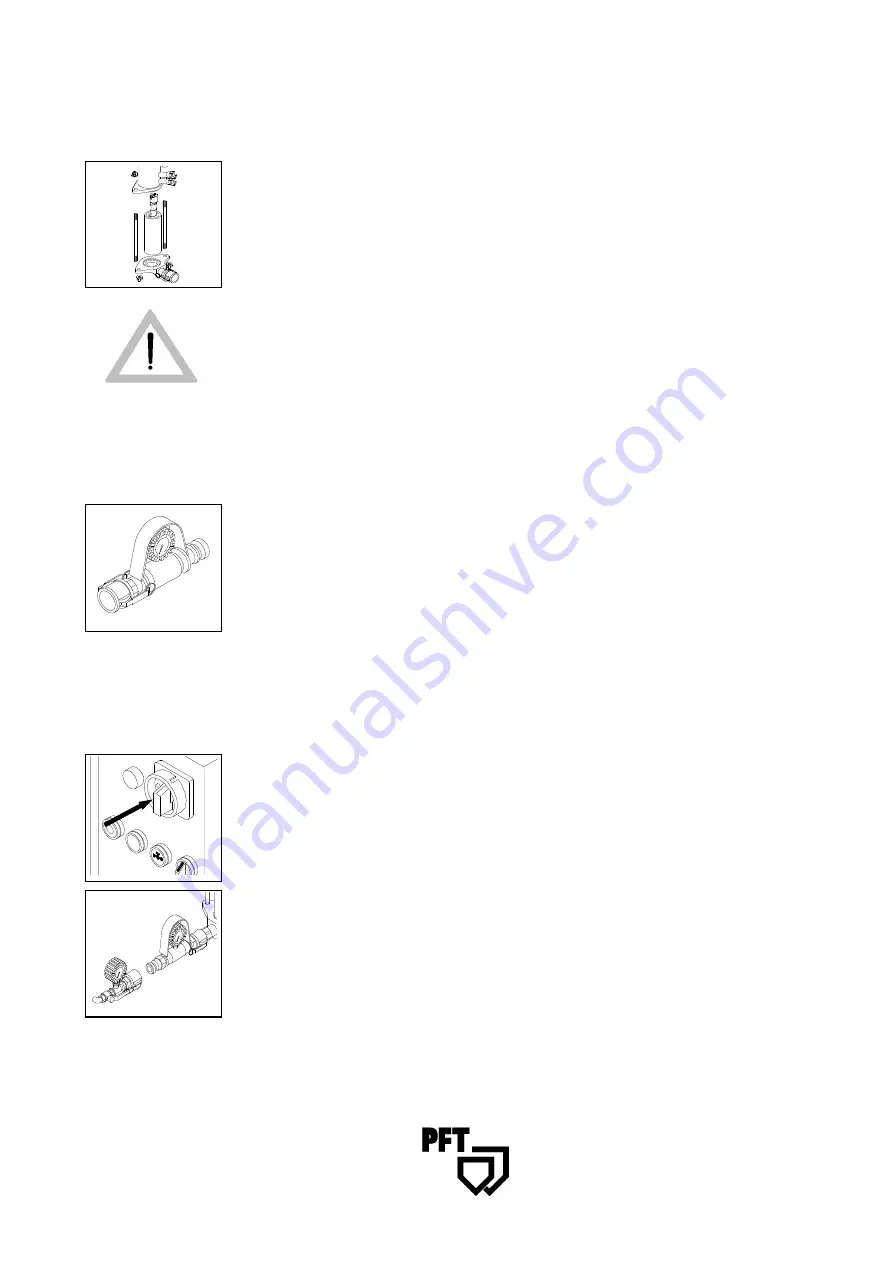

During installation/removal of the mortar pump, the following must be observed:

- the main switch must be switched off during assembly.

Furthermore observe that:

- a new rotor and stator must be run in; real pressure values can only be determined

after the first spraying.

- pump components which neither attain the required conveying pressure nor

maintain the required backpressure are worn out and must be replaced.

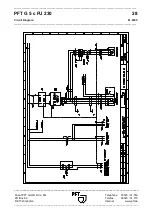

Checking the conveying pressure and backpressure

- Connect 10 m conveying hose

- Connect the pressure tester to outlet tap at end of the hose

- Open valve

- Switch on machine and let water run until water emerges from the outlet tap (let

hose bleed)