____________________________________________________________________________________________________________

PFT G 5 c FU 230

19

Mortar consistency / Spraying guns and nozzles / Interruption of work

01.2005

____________________________________________________________________________________________________________

________________________________________________________________________________________

Knauf PFT GmbH & Co. KG

Telephone

09323 / 31-760

PO Box 60

Telefax

09323 / 31-770

D-97343 Iphofen

Internet

www.pft.de

________________________________________________________________________________________

NOTE:

If work is done without air (e.g. when pumping flow screed), the machine is switched

on and off via 42 V remote control. For this purpose, the blind plug must be removed

from the coupling and the remote control plug connected.

Mortar consistency

The mortar consistency is correct when the material on the surface being sprayed

flows into itself forming a consistent coat (we recommend that you apply material on

wall surfaces from top to bottom). If the material is too dry, even mixing and spraying

cannot take place. There may be clogging in the hose. Pumping components are

thus subject to greater wear and tear.

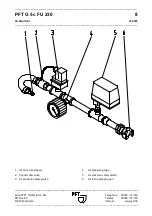

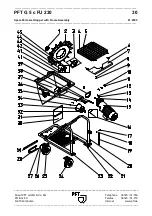

Spraying guns and nozzles

Use spraying nozzles of 10, 12, 14, 16 or 18 mm, depending on the mortar consis-

tency. Larger nozzles reduce the projection speed and thus the rebound effect.

Smaller nozzles create better atomization. Note that the gap between the air nozzle

tube and the nozzle outlet should correspond to the diameter of the nozzle (see also

page 12).

Interruption of work

Follow all instructions from the mortar manufacturer when interrupting spraying work.

It is recommended to clean the pump prior to longer interruptions. To do so, see the

corresponding step on page 20 - Measures at the end of work and when cleaning.

Every interruption of the spraying procedure results in minor irregularities of the

mortar consistency. This normalizes however, as soon as the machine has been

working for a short while. So do not change the water supply each time you detect

irregularities, but instead wait until the consistency of the mortar emerging at the

spraying gun has self-adjusted.