____________________________________________________________________________________________________________

PFT G 5 c FU 230

24

Clearing Hose Blocks

01.2005

____________________________________________________________________________________________________________

________________________________________________________________________________________

Knauf PFT GmbH & Co. KG

Telephone

09323 / 31-760

PO Box 60

Telefax

09323 / 31-770

D-97343 Iphofen

Internet

www.pft.de

________________________________________________________________________________________

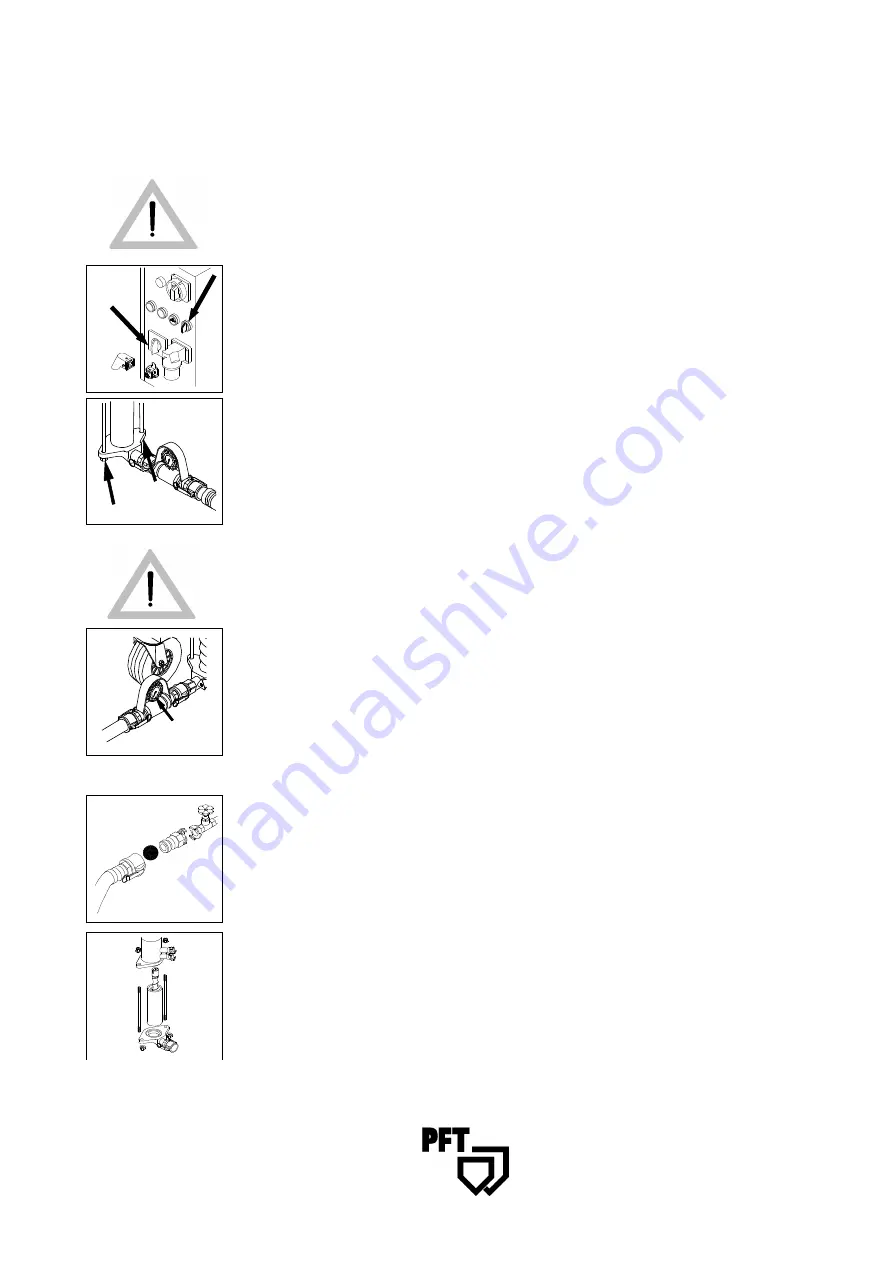

WARNING!

In accordance with the safety regulations of the Builder’s Guild, all personnel clearing

hose blocks should wear safety goggles and should position themselves in such a way

as to avoid injury through discharged mortar.

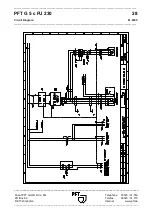

- Switch off star wheel motor (2)

- Run pump motor briefly in reverse, to do so:

- cover outlet opening of pump tube with foil

- “Reverse run” (3) (water intake is automatically interrupted) until pressure at mortar

pressure gauge has fallen to 0 bar

- Loosen nut on pressure flange lightly so that entire residual pressure is released

- Release hose coupling and clean hose

To remove residual mortar from the mortar hose, see page 20 Cleaning the hose.

Measures to take in the case of power failure/no water supply

WARNING!

Check that all hoses are depressurized before opening the couplings (observe mortar

pressure gauge display)!

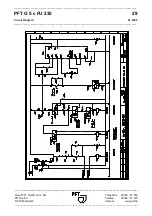

Measures to take in the case of power failure

The mortar hoses must be cleaned immediately. Cleaning can be done at the water

intake valve. To do so, connect the cleaner coupling (in the tool bag) to the mortar

hose first and then to the water intake valve. Force the mortar out by opening the water

valve and then clean using water-soaked sponge balls.

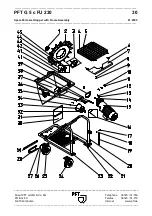

Loosen tie rod screws, remove pump, press rotor out of the stator and clean carefully.

Clean pressure flange or agitator (ROTOMIX or ROTOQUIRL). Clean the mixing area

and mixing shaft with water and spatula. Then assemble the pump and prepare for

service.

1

2