____________________________________________________________________________________________________________

PFT G 5 c FU 230

26

Maintenance

01.2005

____________________________________________________________________________________________________________

________________________________________________________________________________________

Knauf PFT GmbH & Co. KG

Telephone

09323 / 31-760

PO Box 60

Telefax

09323 / 31-770

D-97343 Iphofen

Internet

www.pft.de

________________________________________________________________________________________

Press motor flow button. The water is now blown out of the manifold by compressed

air! (at 1.5 bar for approx. 1 minute).

Empty mixing pump by folding up the entire pump component.

Disconnect and clean mortar hoses.

The machine is now completely empty with the exception of a small rest in the screw

pump. The machine must however still be started carefully the next day.

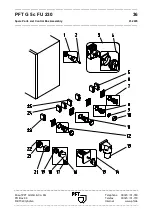

Transport

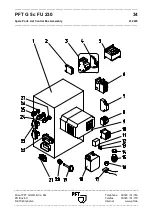

Prior to transporting the mixing pump using a crane, all loose parts (compressor) must

be removed first.

Observe the ultimate load for the ropes. (min. 350 kg).

First disconnect the power supply, then all other cable connections.

Remove water supply lines.

If required, dismount mixing tube.

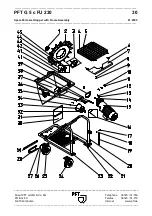

The PFT G 5 c FU 230 mixing pump consists of several units (mixing tube, motor with

tilt flange, material hopper) that can be transported separately.

WARNING!

Check that all hoses are depressurized before opening the couplings (observe mortar

pressure gauge display)

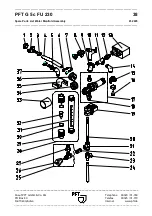

Maintenance

Clean the compressor’s filter on a weekly basis, depending on operation. Repeat this

procedure if required.

Water inlet filters in the pressure reducer should be removed and cleaned every two

weeks, replace if required.

Check brass screen in water inlet on a daily basis.