PFT G 5 SUPER

Operating Manual

Issued 11.2008

Knauf PFT GmbH & Co.KG

19

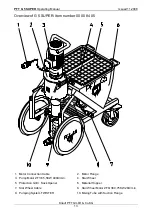

Settings

Safty switch

Machine on

Machine off

Water

2,2 bar

1,9 bar

Air

1,5 bar

1,9 bar

Compressor

2,5 bar

3,1 bar

Compressor Safety Valve

Compressor on

Compressor off

Compressor

2,5 bar

3,1 bar

Compressor Safety Valve

4,

0 bar against completely closed air pipe (factory setting and secured with

knurled screw)

Pressure reducing valve:

1,9 bar at max. throughput

Gap : Air Nozzle Pipe

The gap between the air nozzle tube and spraying cap should correspond

to the diameter of the spraying cap.

e.g.: 14 mm spraying cap = 14 mm gap.

Direction of rotation of the star wheel motor

The star wheel usually works independently of the direction of rotation. If a

SILOMAT conveying system is being used, we recommend a clockwise

direction of rotation (factory setting). This ensures that the pump motor also

runs in the correct direction.

Summary of Contents for G 5 SUPER

Page 48: ...PFT G 5 SUPER Operating Manual Issued 11 2008 Knauf PFT GmbH Co KG 48...

Page 58: ...PFT G 5 SUPER Operating Manual Issued 11 2008 Knauf PFT GmbH Co KG 58 Circuit Diagramm...

Page 59: ...PFT G 5 SUPER Operating Manual Issued 11 2008 Knauf PFT GmbH Co KG 59 Circuit Diagramm...

Page 60: ...PFT G 5 SUPER Operating Manual Issued 11 2008 Knauf PFT GmbH Co KG 60 Circuit Diagramm...

Page 61: ...PFT G 5 SUPER Operating Manual Issued 11 2008 Knauf PFT GmbH Co KG 61 Circuit Diagramm...

Page 63: ...PFT G 5 SUPER Operating Manual Issued 11 2008 Knauf PFT GmbH Co KG 63 Notes...