PFT G 5 SUPER

Operating Manual

Issued 11.2008

Knauf PFT GmbH & Co.KG

25

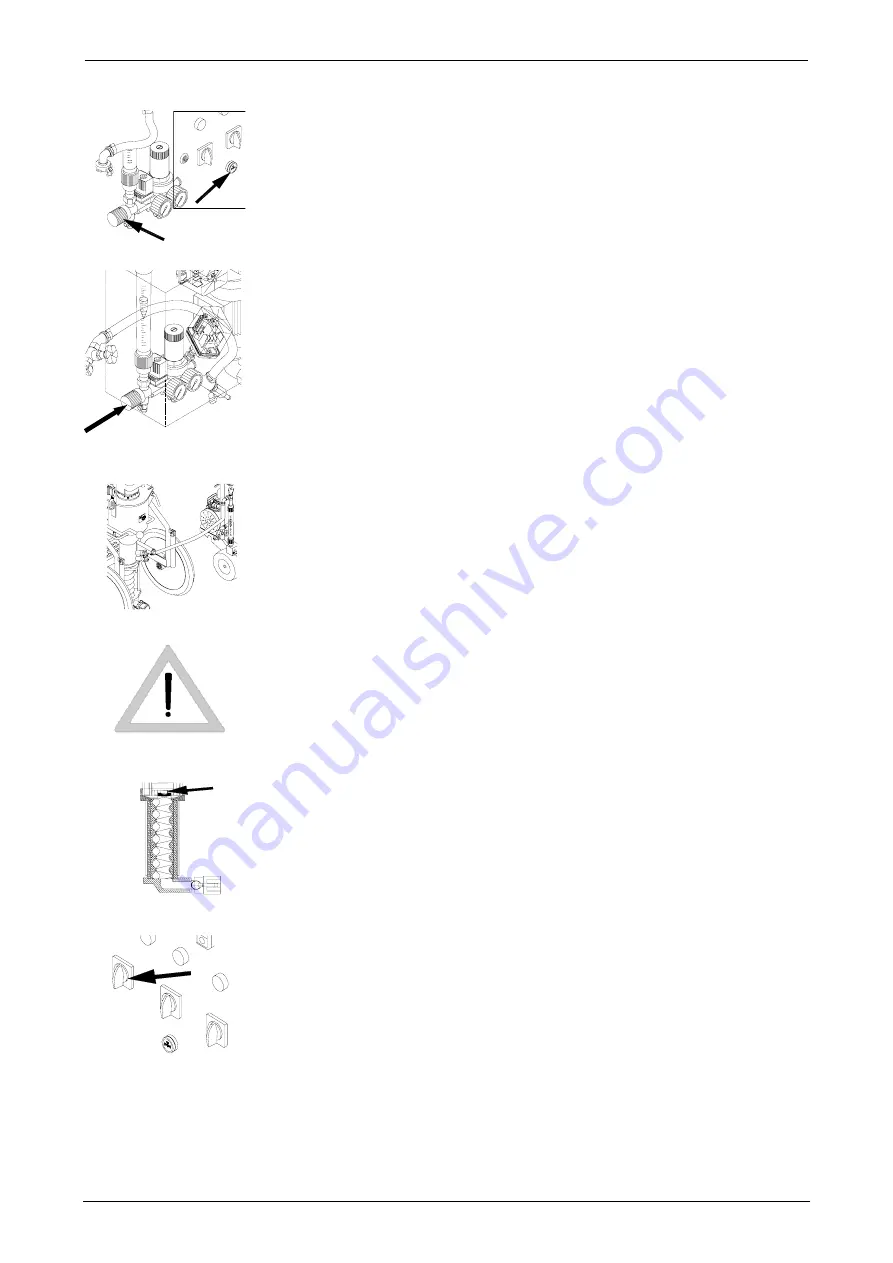

Press water flow button (1) (water pump should be running). Set

approximate amount of water with needle valve (2).

Setting the water factor

Adjust the expected water volume on the needle valve (2).

Observe the specifications of the material manufacturer.

During operation:

Every interruption of the spraying procedure results in minor irregularities of

the mortar consistency. These normalise, however, as soon as the machine

has been working for a while. Therefore do not change the water quantity

each time you detect irregularities, but instead wait until the consistency of

the material emerging at the spray gun has self-adjusted.

Connect the water hose of the water flow meter to the top water inlet of the

mixing tube.

WARNING!

By removing the 7-pin plug of the mixing pump you can interrupt power

supply

(safety measure). To restart machine press green button (on).

Press water flow button briefly. The mixing chamber should contain enough

water so that the top of the rotor is covered. Watch out for loss of water. If

you lose water, the rotor may not be working properly.

Check water level (can be done with tilted pump motor).

The TWISTER D 6-3 pump should always be pre-wetted!

Set star wheel switch on “Hand“. You can set the star wheel on:

“HAND” (Manual Operation)

“0”

“AUTOMATIC”

1

2

2

Summary of Contents for G 5 SUPER

Page 48: ...PFT G 5 SUPER Operating Manual Issued 11 2008 Knauf PFT GmbH Co KG 48...

Page 58: ...PFT G 5 SUPER Operating Manual Issued 11 2008 Knauf PFT GmbH Co KG 58 Circuit Diagramm...

Page 59: ...PFT G 5 SUPER Operating Manual Issued 11 2008 Knauf PFT GmbH Co KG 59 Circuit Diagramm...

Page 60: ...PFT G 5 SUPER Operating Manual Issued 11 2008 Knauf PFT GmbH Co KG 60 Circuit Diagramm...

Page 61: ...PFT G 5 SUPER Operating Manual Issued 11 2008 Knauf PFT GmbH Co KG 61 Circuit Diagramm...

Page 63: ...PFT G 5 SUPER Operating Manual Issued 11 2008 Knauf PFT GmbH Co KG 63 Notes...