Mixing pump G 4 X Super / G 4 X XL / Part 2 Overview, operation and service

Operation

Possible causes:

Heavily worn mortar hoses

Badly greased mortar hoses

Residual water in mortar hose

Clogging of the pressure flange

Severe restriction at the couplings

Kink in the mortar hose

Leaks at the couplings

Poorly pumping and separated materials

Earlier damage to the mortar hose

Should the pressure in the mortar hose exceed 60 bar in

the event of a machine failure due to material clogging,

replacement of the mortar hose is recommended as there

might be damage in the hose that is not externally visible.

5.14.6

Removal of clogging in hoses

WARNING

Danger from discharged material!

Never detach hose couplings if the feed pressure has

not been fully released! Material to be conveyed can be

discharged under pressure and cause injuries particularly

to the eyes.

Persons commissioned with the cleaning of clogged

hoses have to wear personal protective equipment

(protective goggles, gloves) for safety reasons, and must

position themselves in such a way that they cannot be hit

by discharged material. Other persons have to clear the

area.

5.14.6.1 Let the pump run backwards

4

2

3

1

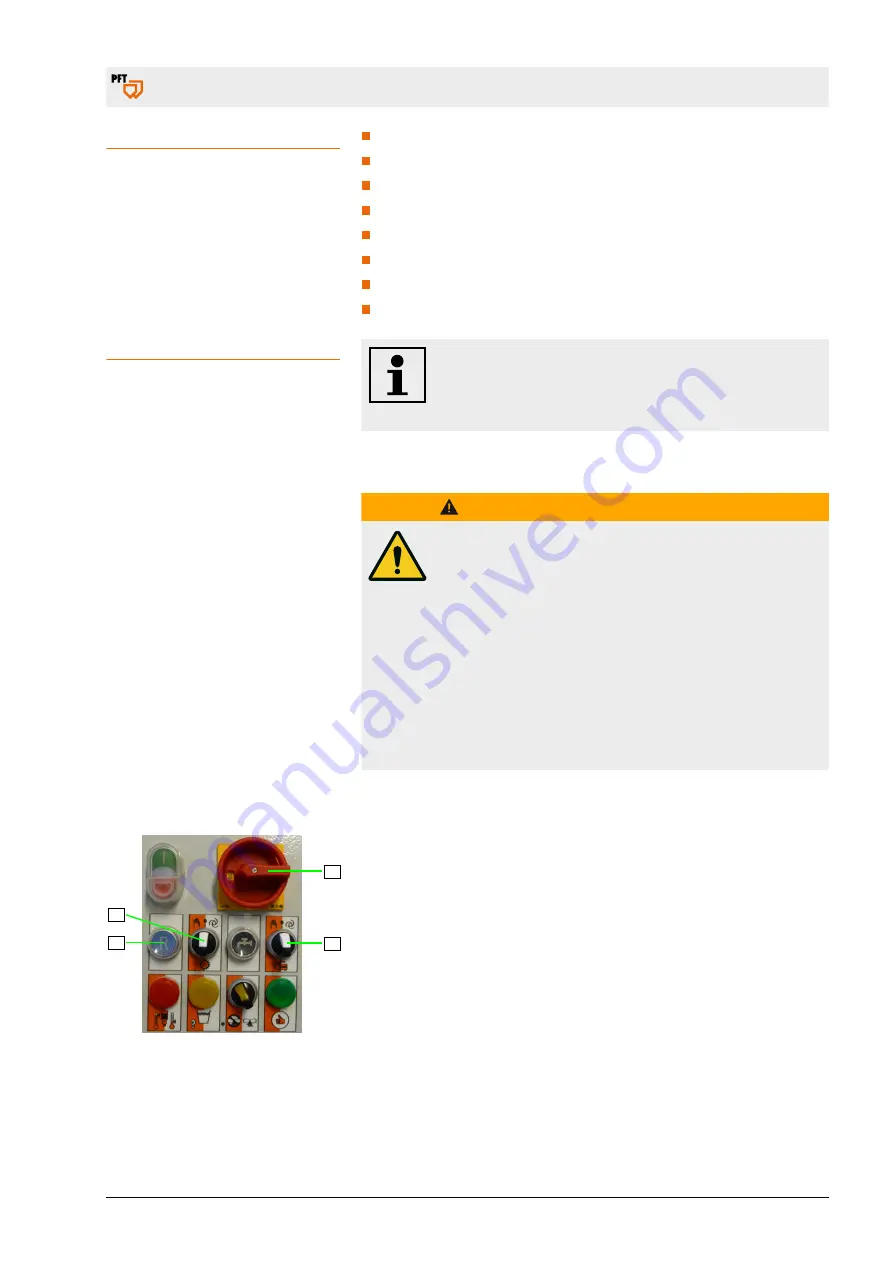

Figure 78: Reverse operation

1. Turn the star wheel selector switch (1) to the "0" position.

2. Turn the booster pump selector switch (2) to the "0" position.

3. Move the blue "Release pump" pushbutton (3) backwards until the

pressure at the mortar pressure gauge has dropped to "0 bar".

4. Turn the main switch (4) to "OFF".

page 57 / 72