PFT continuous mixer HM 2002 Overview - Operation - Spare parts lists

Maintenance work

38

2017-03-14

37.3 Maintenance plan

The following paragraphs describe the maintenance works that are

require for an ideal and trouble-free operation.

In the event that increased wear is detected during regular checks,

the required maintenance intervals have to be shortened according

to the actual signs of wear.

Should you have any queries regarding maintenance works and

intervals contact the manufacturer, see page 2 for service

addresses.

Interval

Maintenance work

To be carried out by

daily

Clean/replace strainer screen in water inlet.

Operator

38 Maintenance work

38.1 Strainer screen

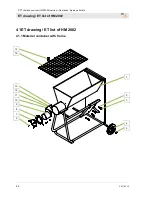

Fig. 48: Strainer screen in water inlet.

Check the strainer screen in water inlet daily:

1. Remove the strainer screen (1) from Geka coupling.

2. Clean the strainer screen.

3. Replace the sieve in case of heavy contamination.

4. Reinsert the strainer screen

.

Strainer screen with Geka coupling:

Article number 20152000

Implementation by operator.

38.1.1 Strainer screen in pressure reducer

Fig. 49: Strainer screen in pressure

reducer

1. Remove the closure cap (1) from the pressure reducer.

2. Take out the strainer screen (2) and clean (monthly).

3. Replace the screen in case of heavy contamination.

4. Insert screen and screw on the closure cap.

Screen for pressure reducer: Article number 20156000

Execution by service technician.

1

2

1