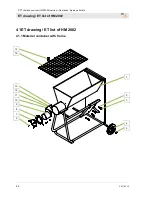

PFT continuous mixer HM 2002 Overview - Operation - Spare parts lists

ET drawing / ET list of HM 2002

2017-03-14

45

ITEM

Qty

Article no.

Article description

1

1

00 00 21 28

On/Off switch of HM 22/2002, 230 V 50 Hz complete with connection cable

and thermal protection 14 A

2

1

20 45 69 42 Thermo switch 10-12 A 230 V 50 Hz

3

1

00 05 44 88

Emergency stop button cover (yellow/red complete with screws) for On-Off

switch of HM 22/2002 230 V 1Ph. (art. no. 00002128)

4

2

20 20 66 02 Safety nut M5, galvanised

5

2

20 20 64 06 Cylinder head screw M5 x 50, galvanised

6

1

20 54 63 00 Cover hood of HM 2000/2002 RAL 2004

7

2

20 54 66 00 V-belt

8

4

20 20 78 11 Flat head screw M8 x 12, galvanised

9

1

20 54 65 00 V-belt pulley diameter 63 mm

10

1

20 20 78 03 Hex. screw M8 x 80 galvanised

11

1

20 54 62 10 Motor fixing angle of HM 2002 RAL 2004

12

1

20 14 19 00 Motor 2.2 KW 230 V 50 Hz 1 Phase

1

00 59 33 73 Motor 2.2 kW 120 V 60 Hz 1 Phase

1

On request

Motor 2.2 KW 230 V 60 Hz 1 Phase

13

1

On request

Capacitor 130 mF D=46 x 84 (Motor 2.2 KW 230 V 50 Hz 1 Phase)

14

1

00 02 12 00 Capacitor 50 myF D=45 x 116 (Motor 2.2 KW 230 V 50 Hz 1 Phase)

15

1

20 44 81 00 Klixon relay type 2CR4-273 (motor 2.2 KW 230 V 50 Hz 1 Phase)

16

1

20 44 80 00 Resistance 0.68 OHM, 12.5 W (motor 2.2 KW 230 V 50 Hz 1 Phase)

17

1

20 54 77 00 Protective cap for HM 2000/2002

18

1

20 54 67 00 Flange bearing unit complete with pivot ball bearing

19

1

00 03 62 43 Y-flange bearing, type FYTB 25TF

20

1

20 54 74 01 Drive shaft complete with clamping pins and feather keys 245 mm

21

1

20 54 64 00 V-belt pulley diameter 355 mm