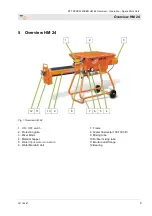

PFT SCREW MIXER HM 24 Overview – Operation – Spare Parts Lists

Setting Up the Machine

22

2017-08-07

Caution!

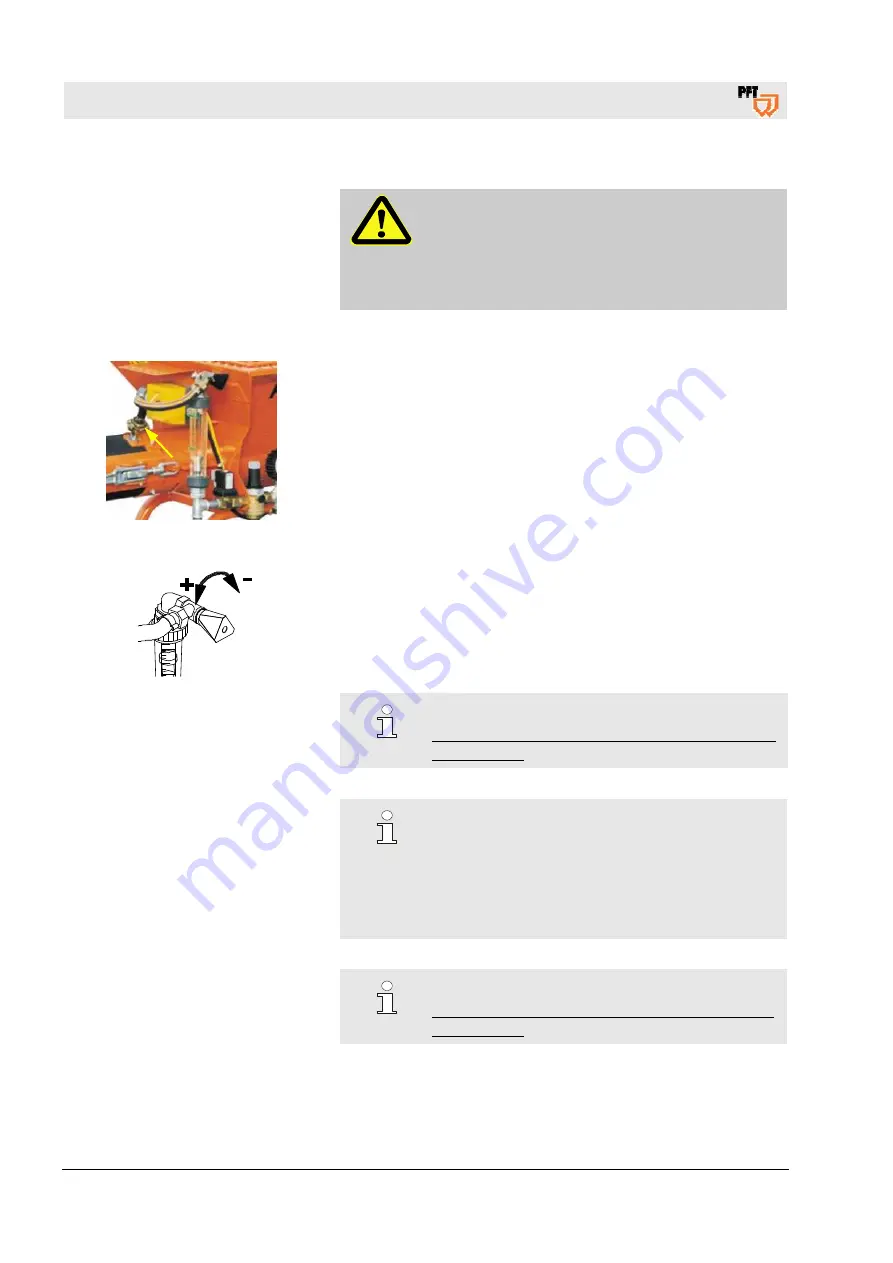

While using stored water from a tank, connect the

suction inlet with a filter.

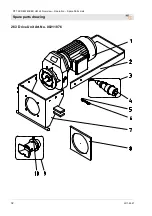

(Item no. 20 47 50 00) ( deaerate water pump )

Connect the water hose of the needle valve to the mixing tube.

When the PFT HM 24 has been completely assembled and

connected, follow these steps:

•

Fill hopper.

•

Switch on the HM 24 at main switch.

Regulate the amount of water at the needle valve.

Mortar Consistency

Adjust the needle valve in such a way that the machine emits

trowel-suited mortar at the mortar outlet.

NOTE:

Follow all material mixing instructions of the mortar

manufacturer!

NOTE:

Interrupting Work!

The length of a break during operation will depend on

the material and on the

conditions at the construction site (e.g. temperature,

humidity etc.)

NOTE:

Follow all material mixing instructions of the mortar

manufacturer!