____________________________________________________________________________________________________________

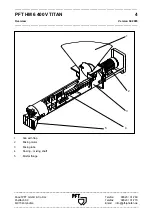

PFT HM 6 400 V TITAN

8

Basic safty instructions

Version 02.2003

____________________________________________________________________________________________________________

_______________________________________________________________________________________

Knauf PFT GmbH & Co.KG

Telefon

09323 / 31-760

Postfach 60

Telefax

09323 / 31-770

D-97343 Iphofen

info@pft-iphofen.de

_______________________________________________________________________________________

The following terms and symbols are used in this manual to highlight important

information:

NOTE:

Information for running the machine efficiently.

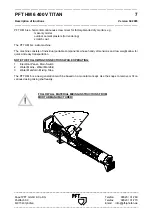

WARNING!

Precautionary information for the prevention of accidents.

WARNING!

The machine should only be operated in perfect working conditions. Comply with all safety instructions in this manual!

Rectify all defects and faults immediately. Proper machine operation includes full compliance with all operating in-

structions, carrying out specified inspections, and complying with maintenance instructions.

The most important safety instructions follow.

Please read them thoroughly

Comply with these instructions in order

to get reliable quality service from the machine.

1.

Follow all safety instructions on the machine. Ensure that all instructions are legible

2.

Inspect the machine once every shift for visible damages and defects. Stop operating the machine immediately

if you notice any changes in safety or operating behaviour. Notify a supervisor immediately.

3.

Do not make any changes to the machine that can jeopardise its safety. Always consult the machine dealer

first. Do not tamper with the machine by equipping it with extra "safety devices."

4.

All spare parts must conform to our technical specifications. Only use spare parts manufactured by PFT.

5.

Only trained personnel should operate the machine. Clearly designate all lines of responsibility for operation,

equipping maintenance and repairs.

6.

Technicians undergoing training in the operation of the machine should be supervised by experienced person-

nel.

7.

Only qualified personnel should work on the machine's electrical system. All electrical work should only take

place under the supervision of a qualified electrician and should comply with electors-technical safety regula-

tions.

8.

Observe all instructions for switching the machine on and off. Watch display lamps for signals.

9.

When the machine is completely switched off for maintenance and repair work, ensure that it cannot switch back

on accidentally. Do this by switching off the main switch, removing the key or by attaching a warning sign to the

main switch.

10. Before cleaning the machine with a water jet, seal all openings that can be damaged through water, e.g. electri-

cal motors and control boxes, thoroughly. After cleaning remove all seals and covers.

11. Use only original fuses with prescribed amps.

12. If work has to be carried out on a voltage-conducting component, a second technician should stand by to switch

off mains in case of an emergency.

13. Disconnect the machine from the mains before you move it, even if you are only moving it a short distance.

Reconnect the machine to the mains properly before starting up again.

14. Set up the machine on stable ground. Secure it from rolling away or moving during operation.

15. Depressor all conveying systems before dismantling them.

16. Have the machine inspected at once a year by a qualified person. The machine should also be inspected other-

wise as required.

17. Use protector for eyes, ears, head, hands, feet’s