PFT Air Compressor LK

402 IV

Overview – Operation – Spare

Parts Lists

Page 24

28.01.2019

5 Start-up

5.1 Set-up

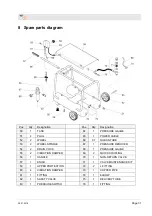

Fig. 4: Set up

To avoid damage to the compressor, it must never be operated with

a transverse or longitudinal inclination of more than 15°.

To ensure proper ventilation, the compressors must be positioned so that

the rear ventilation grille is at least 50 cm from any obstacle to the airflow

and that cleaning and maintenance are easy.

5.2 installation

Fig. 5: Installation

Every compressor is not delivered until it has successfully passed a series

of functional tests by the manufacturer. For optimum operation, please

observe the measures and recommendations listed below.

- Fit the wheels and anti-vibration protection (Fig.3), remove the plug from

the compressor head and fit the intake filter if it is not already fitted (Fig.5).

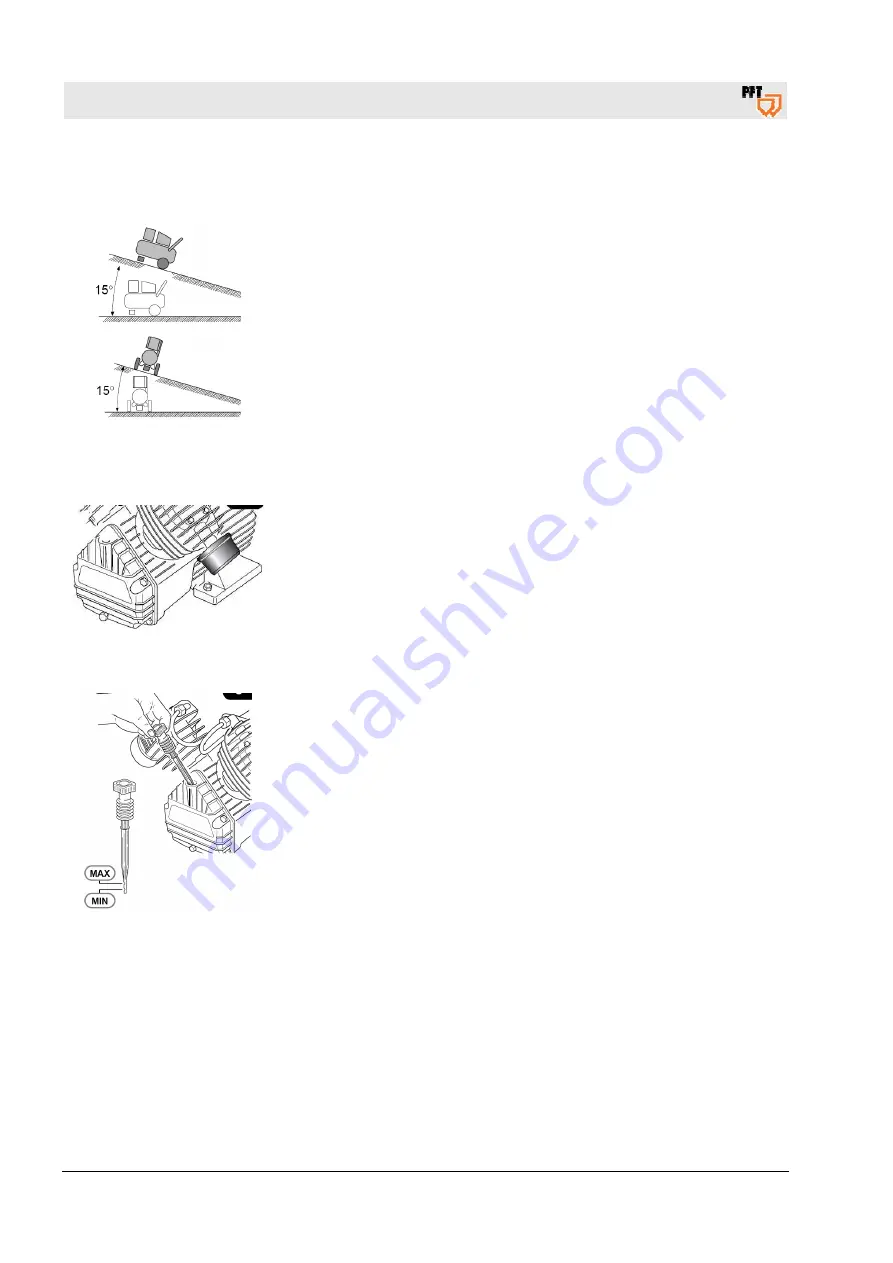

Fig. 6: Test rod

Remove the cap from the housing and insert the oil level dipstick (Fig.6).

- Carefully ensure that the oil level is between the minimum and maximum

value of the test rod (Fig. 6).

- After the first 5 hours of operation, change the oil completely with one of

the oil types listed in the table (see point 6.3).

• Check the compressor voltage and make sure that the supply network is

protected by a magnetic heat insulator and has an earth connection.

The compressor is equipped with a mains plug type CEE 7. Have the

plug replaced by qualified personnel if necessary or to adapt it to local

regulations.

Summary of Contents for LK 402 IV

Page 35: ...28 01 2019 Page 35...