PFT Air Compressor LK

402 IV

Overview – Operation – Spare

Parts Lists

Page 30

28.01.2019

7 Solution

Malfunction

Cause

Correction

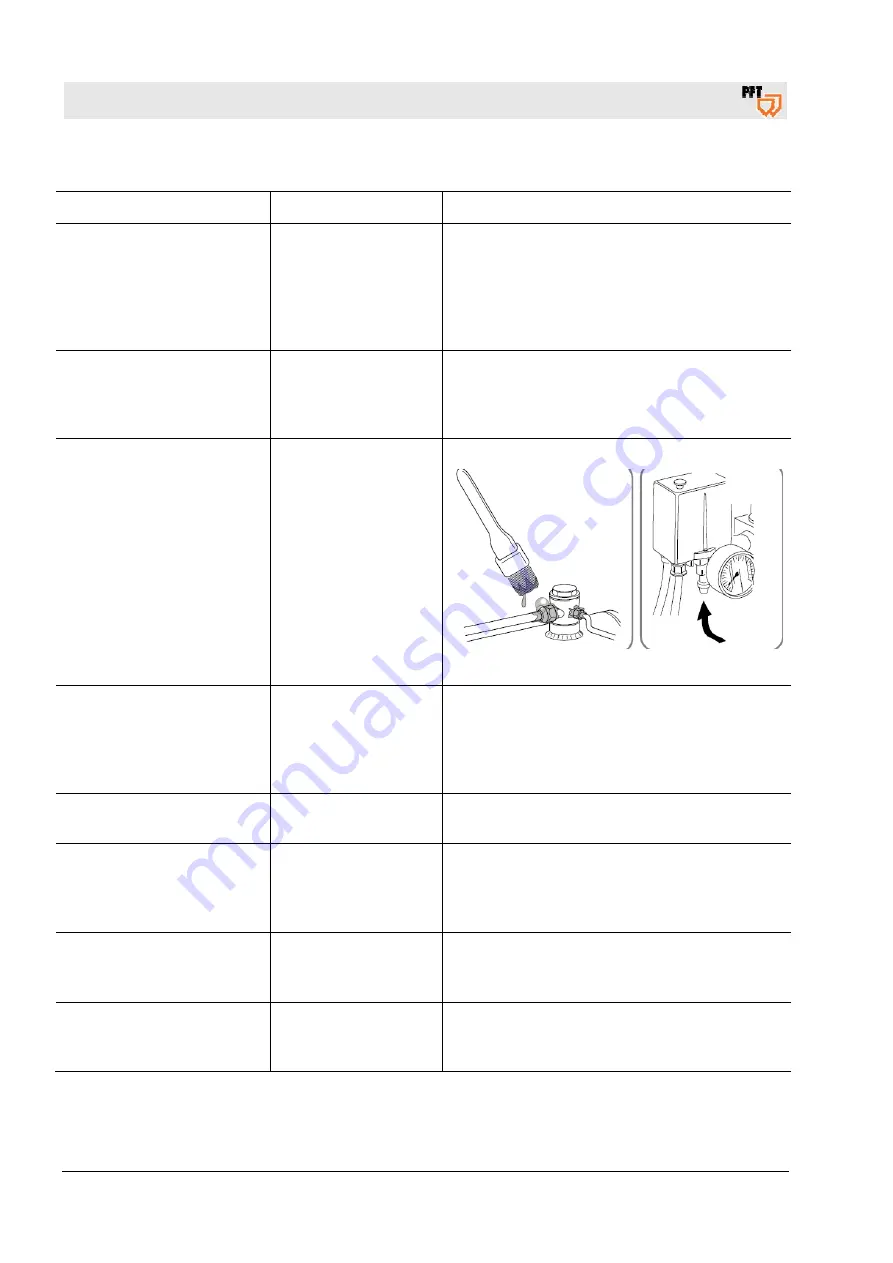

Pressure drop in the tank.

Air outlet from the

connections.

Bring compressor to maximum pressure,

switch off power

and brush all connections with

a brush soaked in soapy water. The air outlets

become visible through air bubbles. Firmly tighten

the relevant connections (Fig. 19). If air outlet

persists, request service.

Air outlet from the pressure

switch valve when the

compressor is at a standstill.

Non-return valve

leaking.

Drain the air from the tank, remove the non-return

valve plug and thoroughly clean the valve seat.

If necessary, replace sealing element D

and reinstall everything (Fig. 18).

Air outlet from the pressure

switch valve when the

compressor is running for

more than 1 minute.

Break of the idle valve.

Replace the valve (Fig. 20).

Fig. 19: Air outlet

Fig. 20: Valve

The compressor switches off

and does not restart.

Motor protection

tripping due to motor

overheating.

Switch off the power supply via the pressure

switch and press the restart button (Fig.8).

If the motor protection should respond again

when the motor is restarted, qualified personnel

must be consulted.

The compressor switches off

and does not restart.

Winding blown.

Call in qualified personnel.

The compressor does not

switch off when the maximum

pressure is reached; the

safety valve responds.

Malfunction or

breakage of the

pressure switch.

Call in qualified personnel.

The compressor does not

charge and heats up

excessively.

Breakage of the head

gasket or a valve.

Switch off the compressor immediately and call in

qualified personnel.

The compressor runs very

loudly and with rhythmic,

metallic beats.

Eating the bronze

bearing or the bush.

Switch off the compressor immediately and call in

qualified personnel.

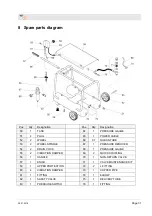

Summary of Contents for LK 402 IV

Page 35: ...28 01 2019 Page 35...