___________________________________________________________________________________________________________

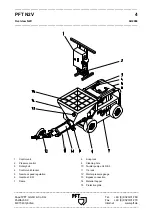

PFT N2V/N2 FU 400V

12

Mortar pump

04/2004

___________________________________________________________________________________________________________

_______________________________________________________________________________________

Knauf PFT GmbH & Co.KG

Tel.

+49 (0) 9323/31-760

Postfach 60

Fax

+49 (0) 9323/31-770

D-97343 Iphofen

Internet

www.pft.de

_______________________________________________________________________________________

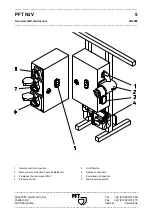

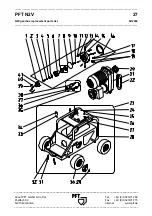

PFT N2V/N2 FU 400 PUMP SYSTEM

The PFT N2V/N2 FU 400 is equipped as standard with a maintenance-free pump

system.

NOTE:

Rotor and stator are subject to wear and must be inspected on a regular basis

and replaced if necessary.

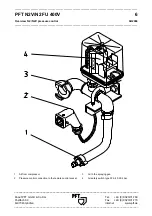

Pressure

The PFT N2V/N2 FU 400 pump unit should attain a pressure of at least 15 - 20 bar

and a backpressure of approx. 6 - 8 bar when the machine is switched off.

Checking the conveying pressure and backpressure

-

Fill the material hopper of the pump with water

-

Connect the 10 m conveying hose

-

Connect the mortar pressure gauge

-

to the hose end of the spraying gun with the tap

-

Open the tap

-

Switch on the machine until water emerges from the spraying gun (bleeding the

hose)

-

Shut the tap

-

Let pump run against pressure until there is no more increase in pressure

-

If the required pressure of 15 - 20 bar is no longer attained, the pump must be

replaced

-

Check the backpressure

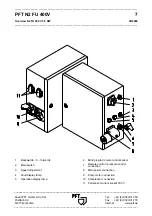

During installation/removal of the pump unit, the following must be observed:

-

The power connection must be disconnected during assembly.

-

A new rotor and a new stator need to be run in; real pressure values can only be

determined after the first spraying.

-

Pump components which neither attain the required conveying pressure nor

maintain the required backpressure are worn out and must be replaced.