___________________________________________________________________________________________________________

PFT N2V/N2 FU 400V

13

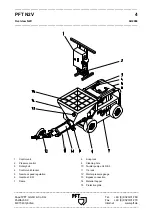

Mortar pump

04/2004

___________________________________________________________________________________________________________

_______________________________________________________________________________________

Knauf PFT GmbH & Co.KG

Tel.

+49 (0) 9323/31-760

Postfach 60

Fax

+49 (0) 9323/31-770

D-97343 Iphofen

Internet

www.pft.de

_______________________________________________________________________________________

WARNING!

The use of a mortar pressure gauge is absolutely imperative according to the safety

regulations of the Builder’s Guild.

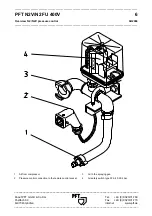

PFT mortar pressure gauge

Some advantages of the mortar pressure gauge:

-

Exact regulation of correct mortar consistency

-

Constant monitoring of correct conveying pressure

-

Early detection of clogging or overloading of pump motor

-

Establishes zero pressure

-

Contributes significantly to the safety of operating personnel

-

Durability of pump components

NOTE

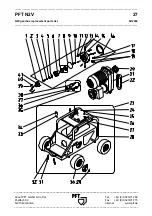

1. Rotor/stator

D 6-3

can be used up to 30 bar operating pressure.

2. The minimum conveying distance depends mainly on how the mortar flows.

Heavy, coarse-grained mortar does not flow easily. Fluid mortars, filling com-

pounds and paint flow easily.

3. Use thicker mortar hoses if you exceed an operating pressure of 30 bar.

4. To avoid machine breakdowns and excessive wear on pump motor, pump shaft

and pump, always use original PFT spare parts such as

PFT rotors / PFT stators / PFT pump shafts / PFT mortar pressure hoses.

These components are compatible with one another and form a single

constructive unit together with the machine. If you do not follow these

recommendations, you will not only lose your warranty rights, but the quality of

the mortar you are producing will also suffer.

WARNING!

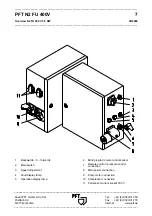

The N2 FU 400 may only be connected to power supplies with an FI safety switch

sensitive to all currents, e.g. PFT intermediate distributor item no. 00 02 12 23.