Part 2 EC Declaration of Conformity Overview – Operation

Preparation of pressure booster pump (accessories)

2020-03-25

21

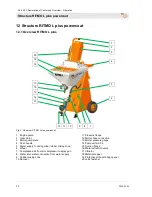

20 Preparation of pressure booster pump (accessories)

Electrical system

Important!

Connect the pump only to plug sockets

with PE contact. In order to increase safety,

we recommend that the electrical circuit to which

the pump is connected has a ground fault interrupt

system with a residual-current circuit breaker with

a rated residual current of 30 mA. This applies

in particular for installation close to water tanks,

ponds, etc.

Hose connection

Important!

Ensure that the suction line or intake line

is connected at the marked position.

If the pump is operated in suction mode, ensure

that the suction line is kept as short as possible.

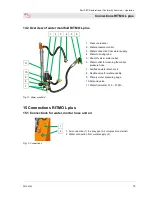

21 Initial operation, filling the pump

Fig.26: Filling the pump

Before putting the PFT High Pressure Pump into operation for

the first time, fill the pump with water so that the air in the pump

housing is displaced.

Fill the pump with water via the water filler plug (1) or the water

inlet (2).

Do not fill too quickly so that the air has time to completely escape

from the housing.

It is advantageous if the suction hose is also filled with water.

21.1 Putting the pressure booster pump into operation

Before operating the pump, observe the following instructions.

The pump must be installed in a horizontal position.

Both the suction line and the pressure line must be connected

before the pump is put into operation. Pay attention to adequate

dimensioning of both lines.

At least 1" for the suction line

At least 3/4" for the pressure line

The hose must be completely air-tight and the end immersed in

the liquid to be pumped to avoid drawing in air.

1

2