Part 2 EC Declaration of Conformity Overview – Operation

Troubleshooting

2020-03-25

49

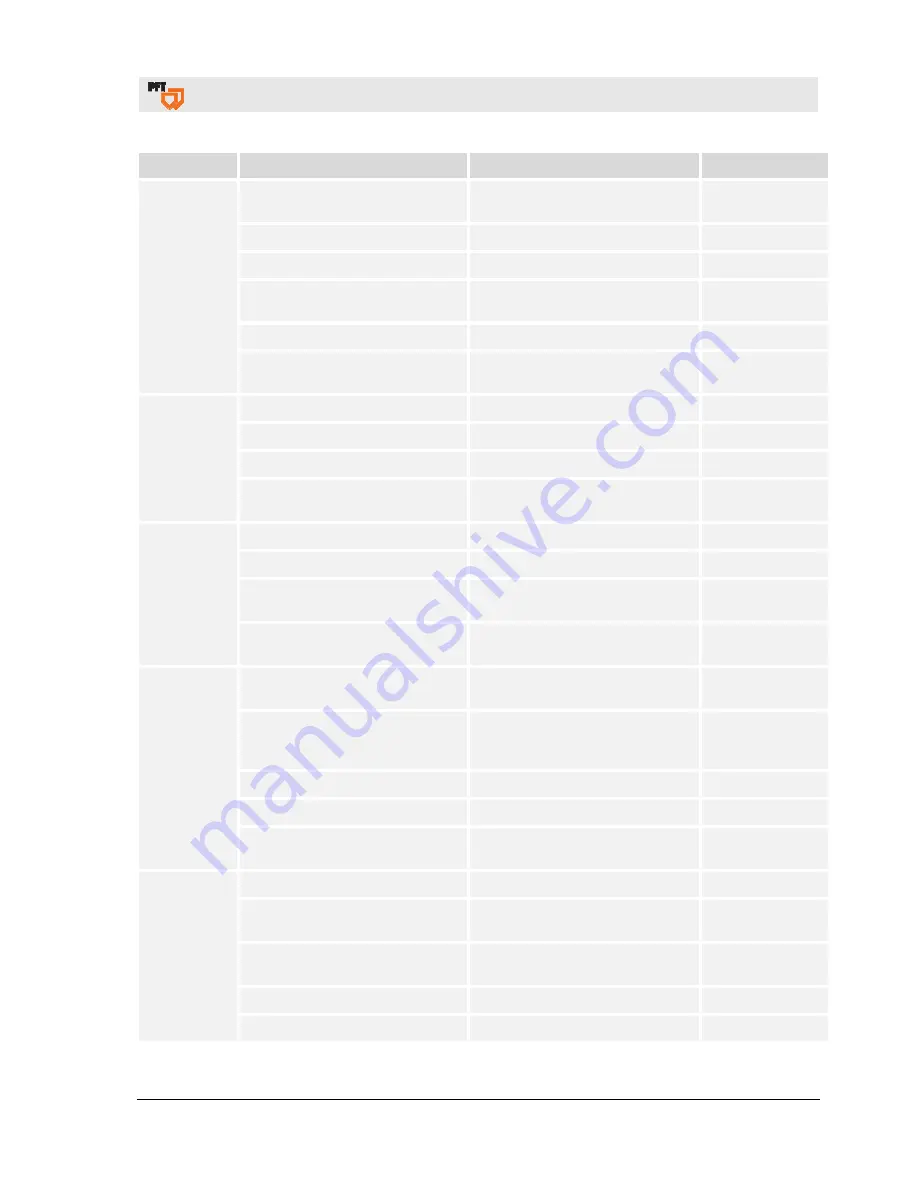

Malfunction

Possible cause

Solution

Performed by

Water not

flowing

(flowmeter

does not

display

anything)

Solenoid valve (bore hole in

membrane blocked)

Clean the solenoid valve

Service technician

Solenoid coil defective

Replace the solenoid coil

Service technician

Pressure reducing valve closed

Open pressure reducing valve

Operator

Water inlet in the rubber mixing

zone blocked

Clean water inlet in the rubber

mixing zone

Operator

Needle valve closed

Open the needle valve

Operator

Cable to solenoid valve defective

Replace the cable to

solenoid valve

Service technician

Pump motor

will not start

Pump motor defective

Replace pump motor

Service technician

Defective connection cable

Replace the connection cable

Service technician

Plug or mounted socket defective

Replace plug or mounted socket

Service technician

Motor protection switch defective

or actuated

Replace or reset motor

protection switch

Service technician

Machine

stops after

a short period

Dirt trap screen is dirty

Clean or replace the screen

Operator

Pressure reducer filter dirty

Clean or replace the screen

Operator

Hose connection or water line

too small

Enlarge the hose connection

or water line

Operator

Water intake line too long or intake

pressure too weak

Connect an additional booster

pump, if necessary

Service technician

Machine will

not switch off

Air pressure safety switch

misadjusted or defective

Set or replace air pressure

safety switch

Service technician

Compressed air hose or gaskets

defective

Replace compressed air hose,

replace gaskets or check

compressor

Service technician

Air tap on spray gun defective

Replace air tap

Service technician

Insufficient compressor output

Check compressor

Service technician

Air supply not connected to

compressor

Connect air supply to compressor

Operator

No mortar

flow (air

bubbles)

Poor mixing in mixing tube

Add more water

Operator

Mortar clogs and narrows mixing

tube inlet

Add more water or clean/replace

mixing shaft

Operator

Material in the mixing shaft has

become wet

Empty mixing shaft,

dry and begin again

Operator

Mixing shaft defective

Replace mixing shaft

Operator

Motor clutch defective

Replace motor clutch

Service technician