Mixing pump RITMO L plus FC-230V Overview – Operation

Description of assemblies

16

2020-11-09

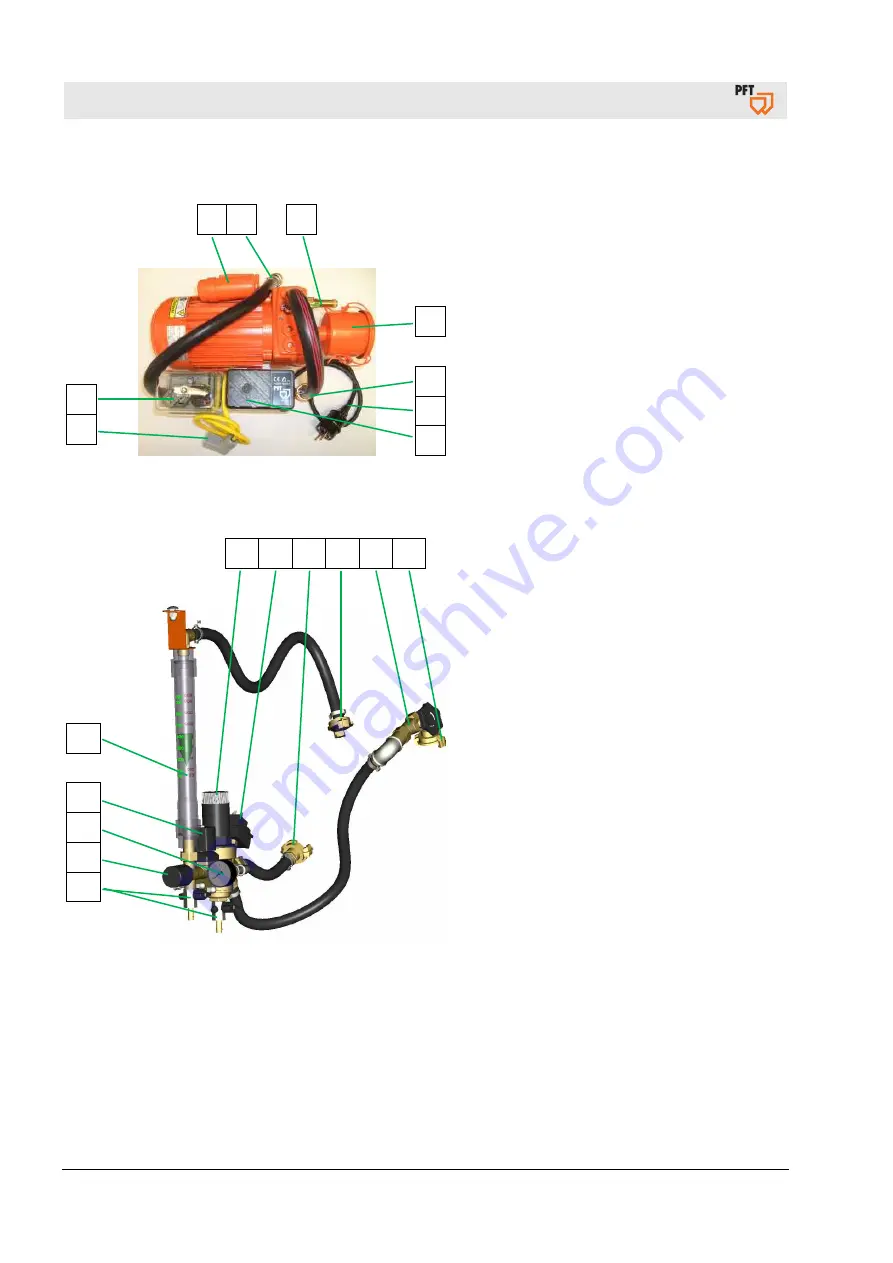

15.2 Overview of air compressor DT4.8 230V

1 2

3

Fig. 12: Air compressor

1. Condenser.

2. Air to spray gun.

3. Safety valve to 1.8 bar.

4. Air filter.

5. Counterflow valve.

6. Electrical connection 230 V.

7. Compressor pressure switch

(switches the compressor ON/OFF).

8. Pressure control connection.

9. Air pressure switch

(switches the machine ON/OFF).

15.3 Overview of water manifold RITMO L plus

1

2

3

4

5

6

Fig. 13: Water manifold

1. Pressure reducer

2. Water pressure monitor.

3. Water connection from water supply.

4. Water to mixing tube.

5. Shut-off valve / water outlet.

6. Water outlet for cleaning the mortar

pressure hose.

7. Antifreeze water drain cock.

8. Needle valve for water quantity.

9. Primary water pressure gauge.

10. Solenoid valve.

11. Water flow meter.

11

10

9

8

7

4

5

6

7

9

8