Mixing pump RITMO XL 400V Overview – Operation

Troubleshooting jobs

40

2019-12-11

27.4 Safety

Personal

The troubleshooting jobs described here cannot be

performed by the operator, unless denoted otherwise.

Some jobs may be performed only by specially trained

technicians or exclusively by the manufacturer. This is

indicated separately in the description of each individual

fault.

Jobs on the electrical system may in principle be performed

only by electricians.

Personal protection equipment

The following protective equipment must be worn while

performing all maintenance jobs:

Work safety clothing

Safety glasses

Safety gloves

Safety shoes

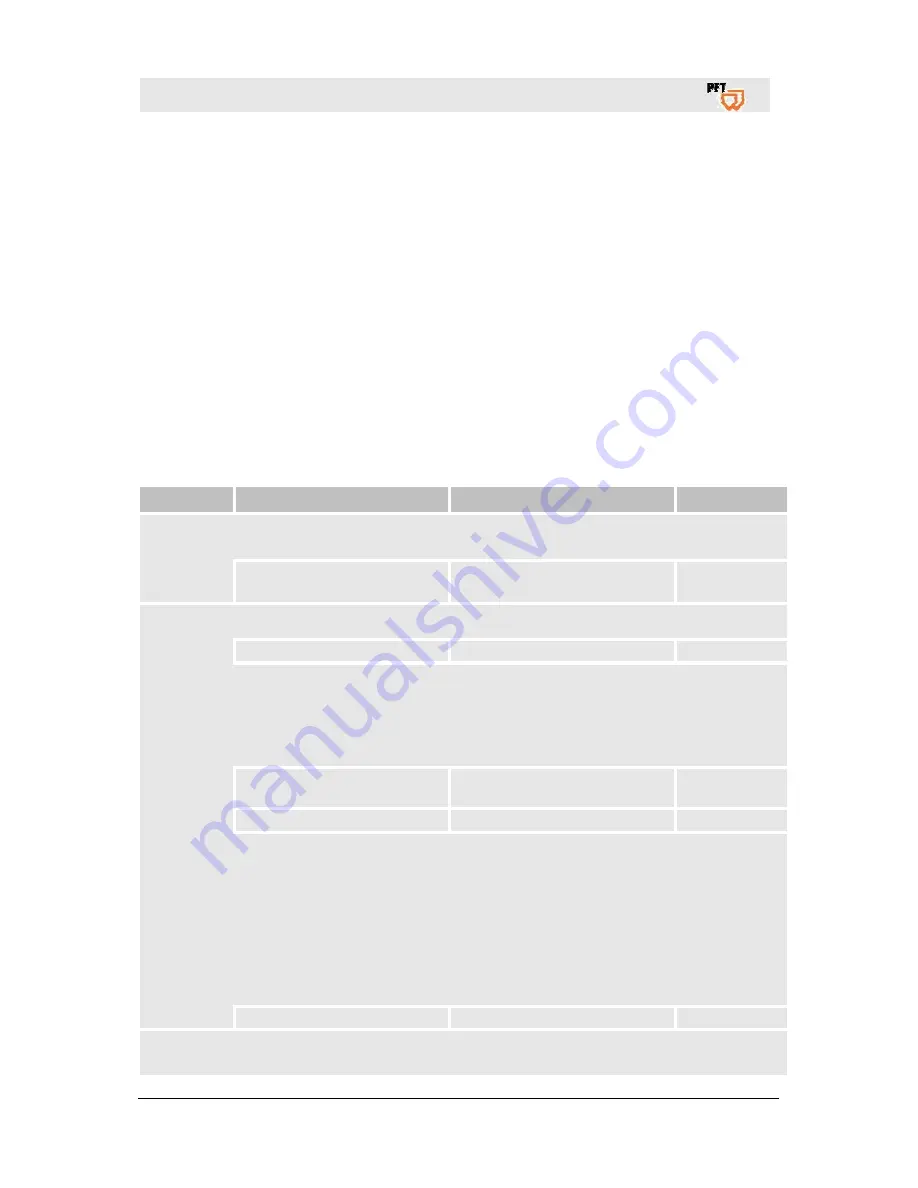

27.5 Faults table

Fault

Possible cause

Troubleshooting

Rectified by

Machine

does not run

water

Water pressure too low

Check water supply line, clean

dirt trapping sieve

Operator

Manometer displays less than

2.2

bar

Check pressure boosting pump

Service

mechanic

Machine

does not run

power

Power supply not OK

Repair power supply cable

Service

mechanic

Master switch not activated

Activate master switch

Operator

FI

-

circuit

breaker

was

triggered

FI - Reset circuit breaker

Service

mechanic

Yellow control lamp (direction of

rotation fault) lights up

On the main reverse switch, push

the metal clamp in the reverse

direction

Operator

Motor circuit breaker tripped

In the control cabinet, turn the

motor circuit breaker to position 1

Service

mechanic

Pushbutton "ON" not pressed

Press pushbutton "ON"

Operator

Contactor is defective

Replace contactor

Service

mechanic

Fuse is defective

Replace fuse

Service

mechanic

Machine

does not run

air

Inadequate pressure fall in the

remote control due to clogged

air pipe or air nozzle tube

Clean clogged air pipe or air

nozzle tube

Operator

Air safety switch displaced

Adjust air safety switch

Service

mechanic

Air compressor not switched on

Switch on air compressor

Operator

Machine

does not run

Too thick material in hopper or

mixing zone

Empty hopper by half and restart

Operator