Mixing pump RITMO XL 400V Overview – Operation

Measures during power failure

44

2019-12-11

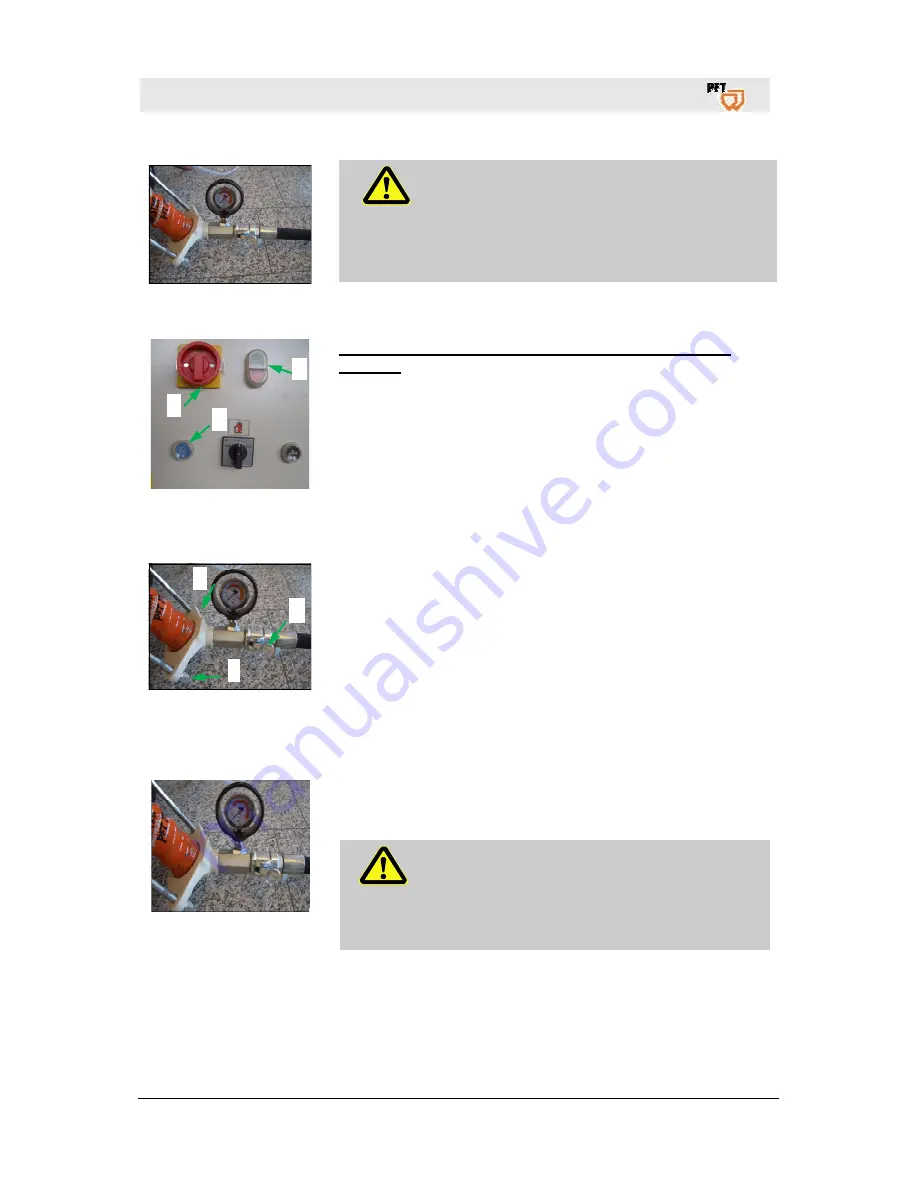

Fig. 69: Mortar pressure

manometer

DANGER!

Excess pressure on the machine!

While opening the machine components, these can

jump out uncontrollably and injure the operator.

– Open the mortar hoses only when the pressure

has fallen to "0 bar".

Fig. 70: Reverse run

Let the pump motor run in the reverse direction for a short

duration:

1. Set main reverse switch (1) to position "I".

2. Press the green pushbutton (2) Control voltage "ON".

3. Press blue key (3) Reverse running direction of rotation (water

supply is stopped automatically), till pressure in mortar pressure

manometer drops to "0 bar".

4. Cover the pressure flange to mortar hose area with film.

28.5 Releasing residual pressure

Fig. 71: Loosening nuts.

1. Loosen the nuts of the tie rod (4) slightly so that possibly existing

residual pressure can escape fully.

2. Detach hose coupling (5) and clean mortar hoses immediately.

3. To remove the remaining material from the mortar hoses,

introduce a flushing hose in the mortar hose and flush the

material out (PFT Flushing hose, Art. No. 00113856).

4. Re-tighten nuts of the tie rod (4) finally.

29 Measures during power failure

Fig. 72: Mortar pressure on "0

bar“

1. Check on the mortar pressure manometer whether the mortar

pressure has dropped to "0 bar". If necessary, release the

pressure by opening the cocks on the spraying gun.

DANGER!

Excess pressure on the machine!

While opening the machine components, these can

jump out uncontrollably and injure the operator.

– Open the machine only when the pressure has

dropped to "0 bar".

4

4

5

1

3

2