Mixing pump RITMO XL 400V Overview – Operation

Checklist for annual expert testing (master copy)

2019-12-11

53

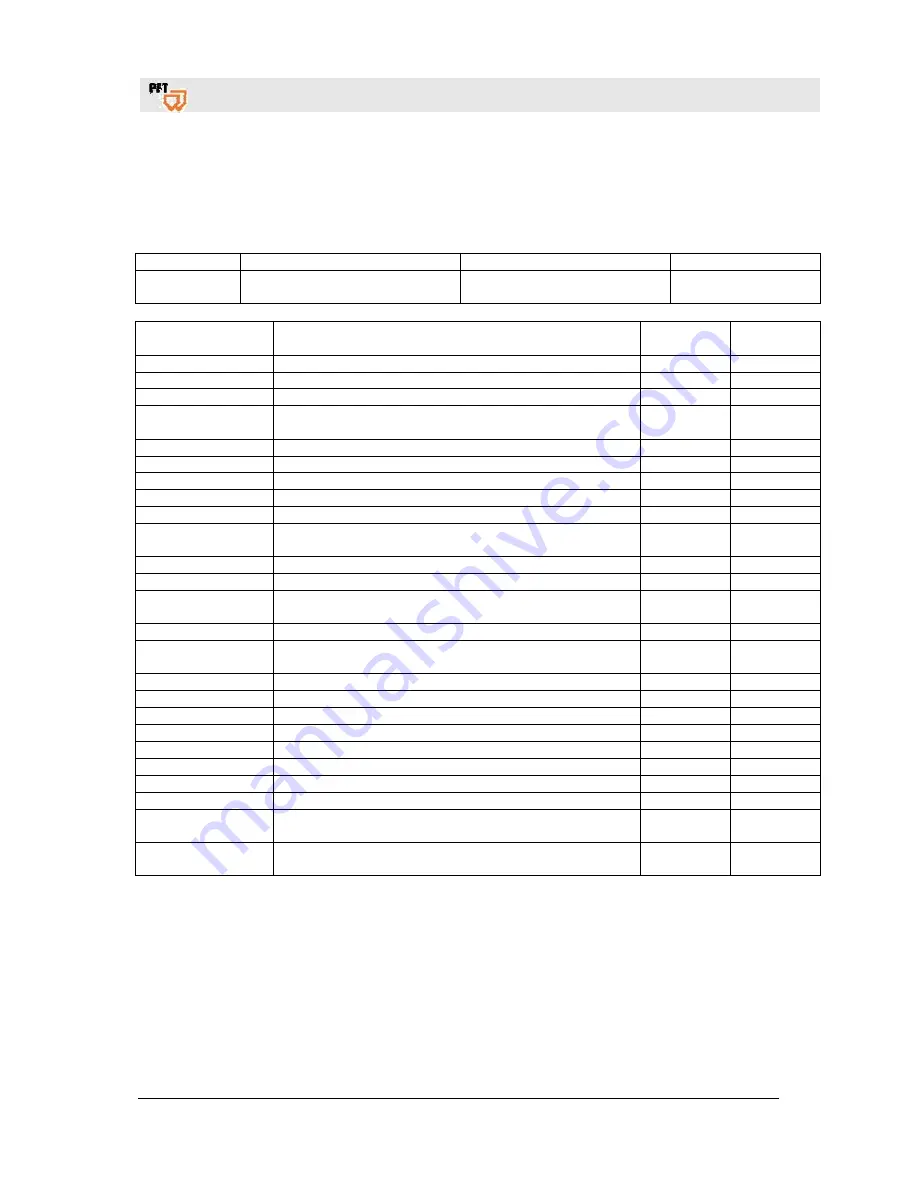

33 Checklist for annual expert testing (master copy)

The expert testing is to be performed once a year according to BGR 183. The machine and control

cabinet get a test sticker as proof of this test. The test log is to be produced on request.

Test date:

Tester:

Signature:

Machine No:

Component

Test characteristic

O

K

Rewor/repl

acement

Material container

Check all welded seams.

Material container

Destruction due to corrosion or deformation?

Material container

Do the hasps work?

Mixing zone

Check wear and tear of rubber mixing zone.

Minimum wall strength 8mm

Mixing coil

Wear test of wedge profile in the mixing area.

Mixing coil

Wear test of pump driver.

Protective grid

Is the protective grid still even?

Undercarriage

Check all welded seams.

Undercarriage

Check that all screw connections have stable seats.

Undercarriage

Check for delay. Stability against fall must be

guaranteed.

Rollers

Do the rollers turn smoothly?

Locking roller

Does the brake function?

Water flow

measuring device

Is the sight glass still transparent and sealed?

Magnet valve

Function check

Pressure reducing

valve

Function check, check setting 1.9 bar.

Control cabinet

Visual check for detectable faults

Control cabinet

Function check

Control cabinet

Are all stickers in readable condition?

Control cabinet

Insulation measurement

Control cabinet

Function check of all circuit breakers.

Control cabinet

Function check of all control lights.

Control cabinet

Check all cable connections for stable seats.

Ratings plate

Available and can be read easily

Operating

Instructions

Available

Mortar pressure

manometer

Function check.