Mixing Pump RITMO XL FU 230/400 reversible Overview – Operation

Description RITMO XL 230 / 400V

26

2019-05-13

Fig. 28: Strainer with mesh filter

The end of the suction line (3) must be fitted with an inlet

strainer with filter screen and integral non-return valve.

An additional fine filter in the suction line is recommended.

NOTE!

The delivery of the pump decreases with increasing

suction line length. Connect the high pressure

pump as close as possible to the water supply

point (pressing is better than sucking).

When all these points have been observed, the pump can be

switched on. Depending on the length of the suction hose,

priming may take a few seconds. If the pump is still not

delivering after a short time, this may have one of the following

causes:

There is still air in the pump and this has to be completely

vented again.

The suction line is not air-tight and the pump is drawing in

air.

The suction-side screen is clogged.

The suction hose is kinked.

The maximum suction head is exceeded.

Important!

The pump must not be allowed to run dry in order

to avoid damage.

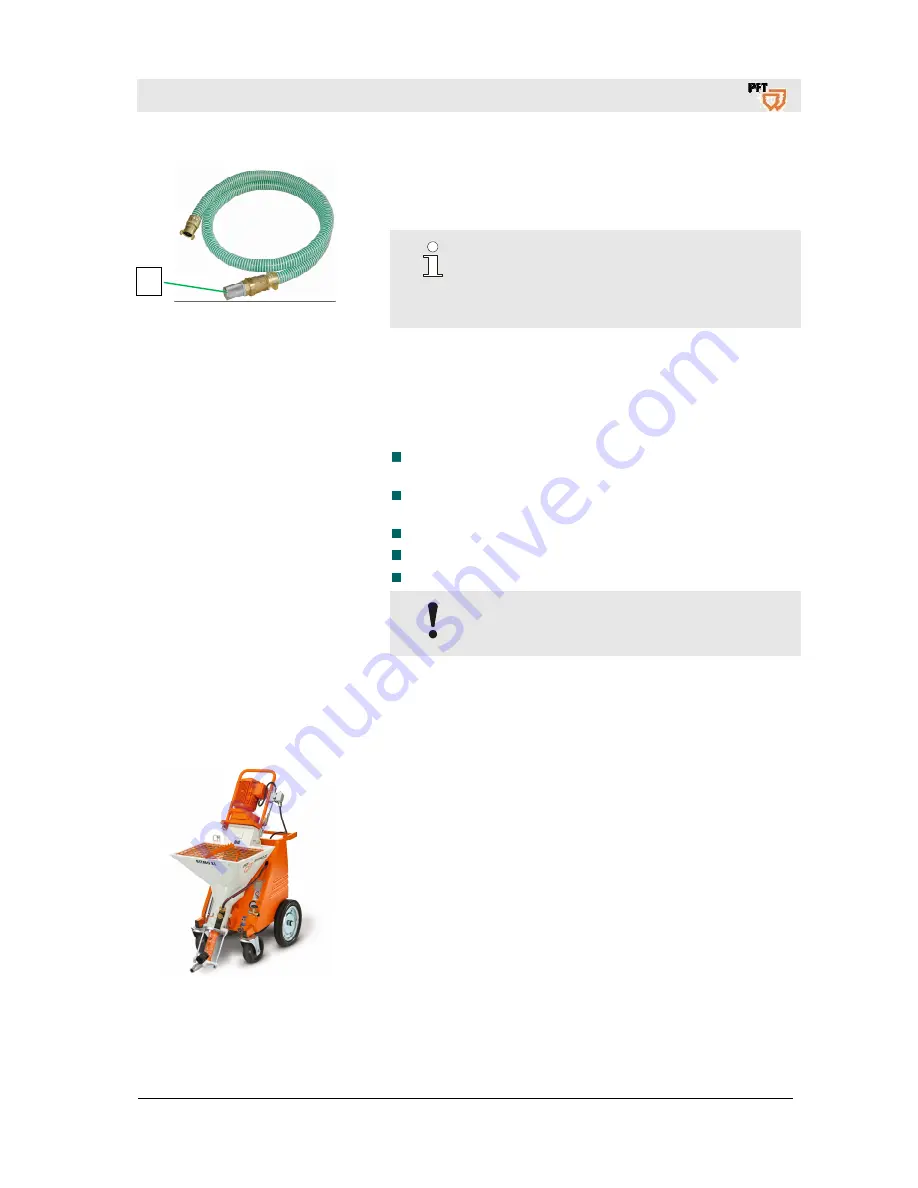

23 Description RITMO XL 230 / 400V

23.1 Operating principle RITMO XL 230 / 400V

Fig. 29: RITMO XL 230 / 400V

The new compact mixing pump RITMO XL with 230V AC or 400V

three-phase drive, specially developed for pumping, spraying and

application of dry mortar ready for use, pasty materials and much

more up to 3 mm grain size.

The pump capacity can be adjusted according to requirements by a

quick pump change. The pneumatic filling of the RITMO XL is

ensured by an optional injection hood in connection with a hopper.

The machine consists of portable single components of handy

dimensions and light weight that allow fast and convenient

transport.

3