Mixing Pump RITMO XL FU 230/400 reversible Overview – Operation

Table of Contents

2019-05-13

3

1

EC Declaration of Conformity ..................... 6

2

Testing .......................................................... 7

2.1

Testing by machine operator ............... 7

2.2

Periodic inspection .............................. 7

3

General information ..................................... 8

3.1

Information regarding the operating

manual ................................................. 8

3.2

Keep the manual for later use ............. 8

3.3

Layout .................................................. 8

4

Spare part lists ............................................. 9

5

Accessories ................................................ 10

6

Technical data ............................................ 11

6.1

General specifications ....................... 11

6.2

Connection values ............................. 11

6.3

Operating conditions .......................... 12

6.4

Performance values ........................... 13

7

Noise level .................................................. 13

8

Vibrations ................................................... 13

9

Type plate ................................................... 13

10

Quality control sticker ............................... 14

11

Dimension sheet ........................................ 14

12

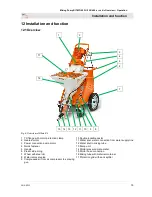

Installation and function ........................... 15

12.1

Overview ............................................ 15

12.2

Overview ............................................ 16

13

Module description .................................... 16

13.1

Mixing tube with material container ... 16

13.2

Undercarriage with compressor and

control cabinet ................................... 17

14

Description of assemblies ........................ 17

14.1

Overview of control cabinet ............... 17

14.2

Change voltage 230 / 400V ............... 18

15

Connections RITMO XL ............................. 18

15.1

Connections for water and air............ 18

15.2

Connection of material hose .............. 18

16

Operating modes ........................................ 19

16.1

Air compressor selector switch .......... 19

16.2

Pump motor selector switch ............... 19

16.3

Water selector switch ......................... 19

17

Accessories ................................................ 20

17.1

PFT - remixer for RITMO XL .............. 20

17.2

Adapter cable ..................................... 20

18

Intended use of fitting block ..................... 21

18.1

Purpose of fitting block ....................... 21

18.2

Purpose of solenoid valve .................. 21

18.3

Purpose of flowmeter ......................... 21

19

Intended use of air compressor ................ 22

19.1

Purpose of air compressor ................. 22

19.2

Safety devices of air compressor ....... 23

19.3

General setup of the air compressor .. 23

19.4

Hot surface on the air compressor ..... 23

20

Description of the PFT pressure booster

pump (accessories) .................................... 24

20.1

Application area of pressure booster

pump .................................................. 24

20.2

Proper use of the machine ................. 24

21

Preparation of pressure booster pump

(accessories)............................................... 25

22

Initial operation, filling the pump .............. 25

22.1

Putting the pressure booster pump

into operation ..................................... 25

23

Description RITMO XL 230 / 400V ............. 26

23.1

Operating principle RITMO XL 230 /

400V ................................................... 26

24

Material ........................................................ 27

24.1

Flowability / conveying property ......... 27

25

Mortar pressure gauge .............................. 27

26

Safety regulations ...................................... 27

27

Transport, packaging and storage ........... 28