Mixing Pump RITMO XL FU 230/400 reversible Overview – Operation

Mortar hoses

40

2019-05-13

37 Mortar hoses

37.1 Preparing the mortar hoses

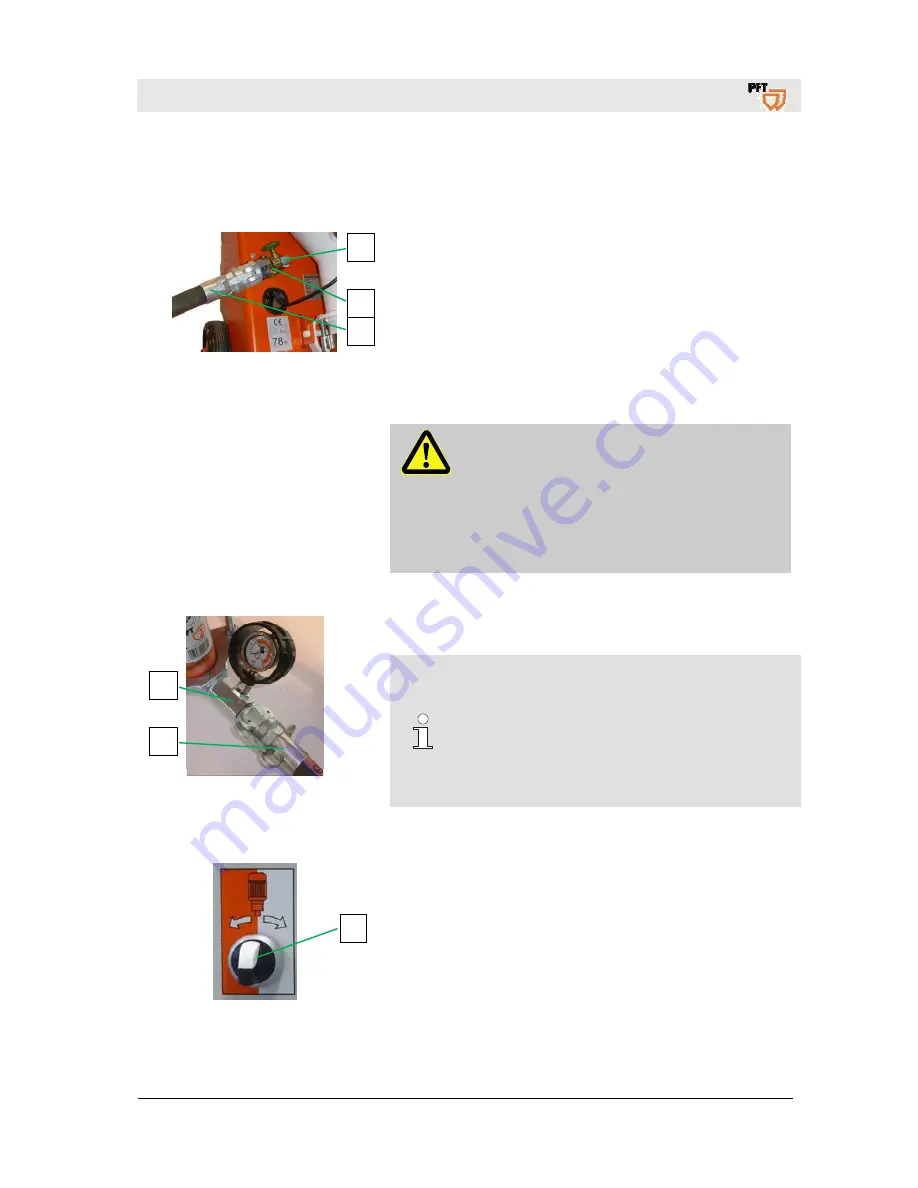

Fig. 56: Preparing the mortar hose

1. Connect the cleaner coupling (1) to the shut-off valve (2).

2. Connect the mortar hose (3) to the cleaner coupling (1).

3. Open shut-off valve (2) and flush mortar hose (3) with water.

4. Remove the mortar hose and cleaner coupling again

and disconnect from one another.

5. Completely empty the mortar hose of water.

6. Prime the mortar hose by wetting it with about 1 litre of

wallpaper paste.

7. The wallpaper paste is pumped through the mortar hose

with the first mixture.

DANGER!

Never detach hose couplings if the mortar hoses

are under pressure (check mortar pressure

gauge). Mixed material can escape under

pressure and lead to serious injuries, especially

eye injuries.

Hoses that tear off can lash wildly and injure

those standing nearby!

37.2 Connecting the mortar hose

Fig. 57: Connecting the mortar hose

1. Connect the mortar hose (1) to the mortar pressure gauge

(2).

NOTE!

Make sure the couplings are clean and connected

properly, and do not leak. Dirty couplings and

rubber seals are leaky and allow water under

pressure to escape, which inevitably leads to

blockages.

Carefully secure risers so that they do not

tear away from their own weight.

2. Lay mortar hoses with a radius large enough so that the

hoses do not kink.

Fig. 58: Switching on

4. Turn the selector switch Pump motor directions of rotation

(3) to the right.

5. Allow the machine to run until all the wallpaper paste

has emerged from the end of the mortar hose.

6. Collect the wallpaper paste with a suitable container

and dispose of it according to regulations.

7. Switch off machine at selector switch (3) (middle position).

2

1

3

2

1

3