Mixing Pump RITMO XL FU 230/400 reversible Overview – Operation

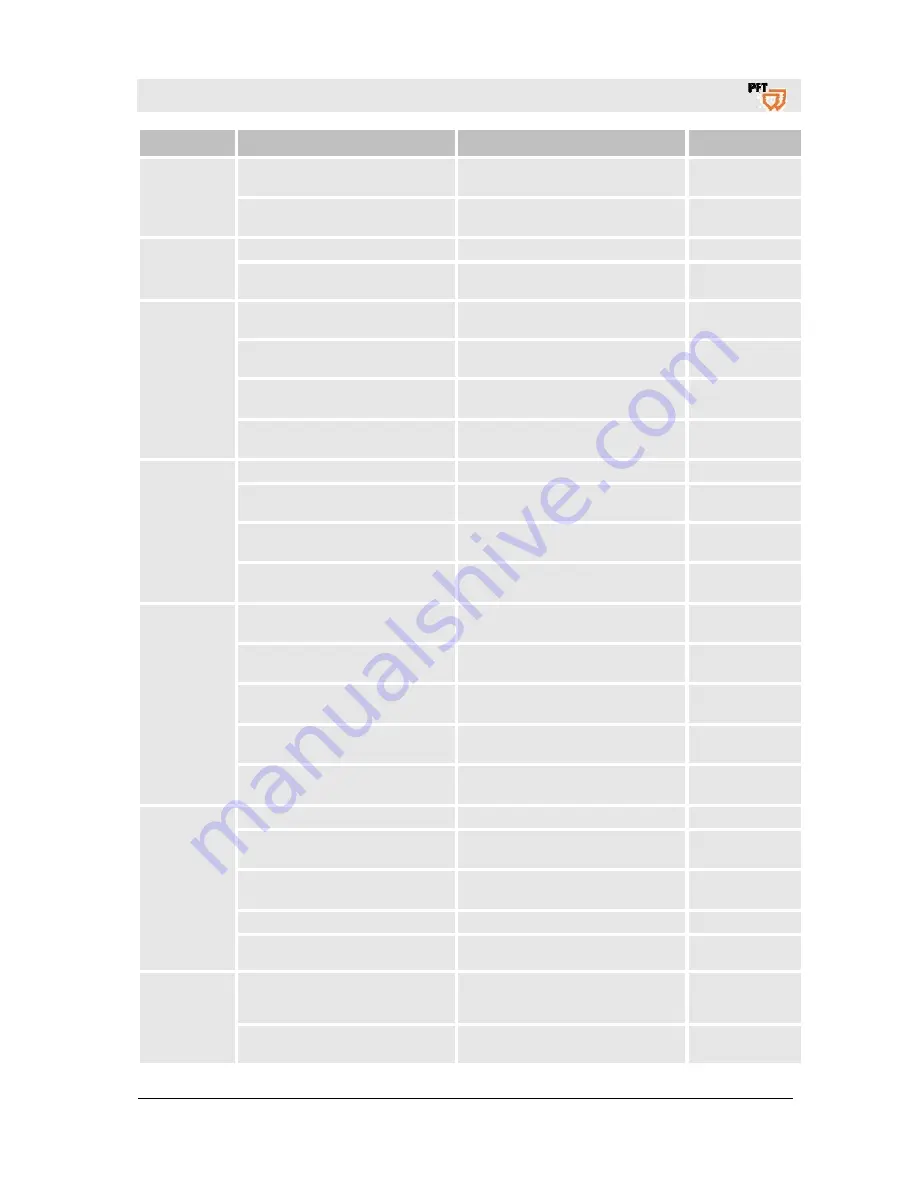

Troubleshooting

48

2019-05-13

Fault

Possible cause

Troubleshooting

Rectified by

not display

anything)

Pressure reduction valve turned

off

Turn pressure reduction valve on

Operator

Water inlet in pump tube is

clogged

Clean water inlet in pump tube

Operator

Needle valve turned off

Open needle valve

Operator

Cable of magnet valve is

defective

Replace cable of magnet valve

Service

mechanic

Pump motor

does not run

Pump motor is defective

Replace pump motor

Service

mechanic

Connecting cable is defective

Replace connecting cable

Service

mechanic

Plug or socket is defective

Replace plug or socket

Service

mechanic

Motor circuit breaker is defective

or has tripped

Replace or reset motor circuit

breaker

Service

mechanic

Machine

stops after a

short

duration

Dirt trapping sieve is clogged

Clean or replace sieve

Operator

Pressure reducer sieve has dirt

deposits

Clean or replace sieve

Operator

Hose connection or water pipe is

too small

Enlarge hose connection or water

pipe

Operator

Water intake pipe is too long or

suction pressure is too weak

If possible, prefix additional

pressure boosting pump

Service

mechanic

Machine

does not

switch off

Air pressure safety switch is not

in correct position or is defective

Adjust or replace air pressure

safety switch

Service

mechanic

Air pressure hose is defective, or

sealings are defective

Replace air pressure hose, replace

sealings or check compressor

Service

mechanic

Air cock on spraying gun is

defective

Replace air cock

Service

mechanic

Compressor output is too low

Check compressor

Service

mechanic

Air pipe not connected to

compressor

Connect air pipe to compressor

Operator

Mortar flow

stops (air

bubbles)

Bad mixing in mixing tube

Add more water

Operator

Material forms clumps and

narrows the mixing tube inlet

Add more water or clean or

replace mixing coil

Operator

Material in mixing tube has

become wet

Clear mixing tube, dry it and then

start afresh

Operator

Mixing coil is defective

Replace mixing coil

Operator

Motor claw is defective

Replace motor claw

Service

mechanic

Mortel flow

"thick-thin"

Too little water

Set water volume up by 10% for

approx 1/2 minute, and then turn

back slowly

Operator

Water safety switch is not in

correct position or is defective

Adjust or replace water pressure

safety switch

Service

mechanic