____________________________________________________________________________________________________________

PFT SILOMAT E

16

Check List

10.2005

____________________________________________________________________________________________________________

_______________________________________________________________________________________

Knauf PFT GmbH & Co.KG

Telephone 09323 / 31-760

Postfach 60

Telefax

09323 / 31-770

D-97343 Iphofen

Internet

www.pft.de

_______________________________________________________________________________________

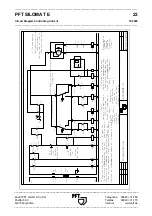

Fault Cause

Remedy

Flap opens and doesn’t

close any more

End switch at motor and drive defective

or misadjusted

Automatic plumb level (K6) FLAP

CLOSED defective

Fill time (K5) faulty

Replace or readjust end switch

Replace end K6

Replace K5

Not enough material in the

machine

Material does not flow out of the silo

Container flap is closed

Level sensor too long

Fill time set too short

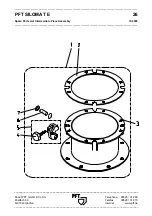

Emulgator filter clogged

Fault in sequence program

Connect vibrator

Open container flap

Attach rotating wing at higher

position

Check K5

Clean see page 18

Red fault lamp lights up

Fault in sequence program, possibly

due to foreign body at or near the flap

Motor safety switch activated

Relieve motor and drive

Remove foreign body

Press motor safety switch

Motor and drive possibly overloaded