PFT

Conveying Pump SWING L

Overview – Operation

– Spare Parts Lists

Filling mater

14/09/2021

29

28.2 Empty the remaining wallpaper paste

Fig. 26: Open the cleaning nozzle

1. Remove the cover (1) from the cleaning nozzle and drain the

remaining wallpaper paste from the material container.

2. Screw on the cover (1) again.

29 Filling material into the SWING L

Fig. 27:

Filling material

Fill the machine with material.

NOTE!

Formation of tunnels:

Due to the material’s physical properties, the material

can partially adhere to the sides of the material

hopper, resulting in the formation of tunnels. The

mortar level in the material hopper should not be

higher than absolutely necessary.

29.1 Check the mortar consistency

Fig. 28: Consistency checking tube

1. Connect the consistency checking tube to the mortar pressure

gauge.

2. Place a bucket or tub under the consistency checking tube.

Item number: 20104310 Consistency checking tube 35 male part.

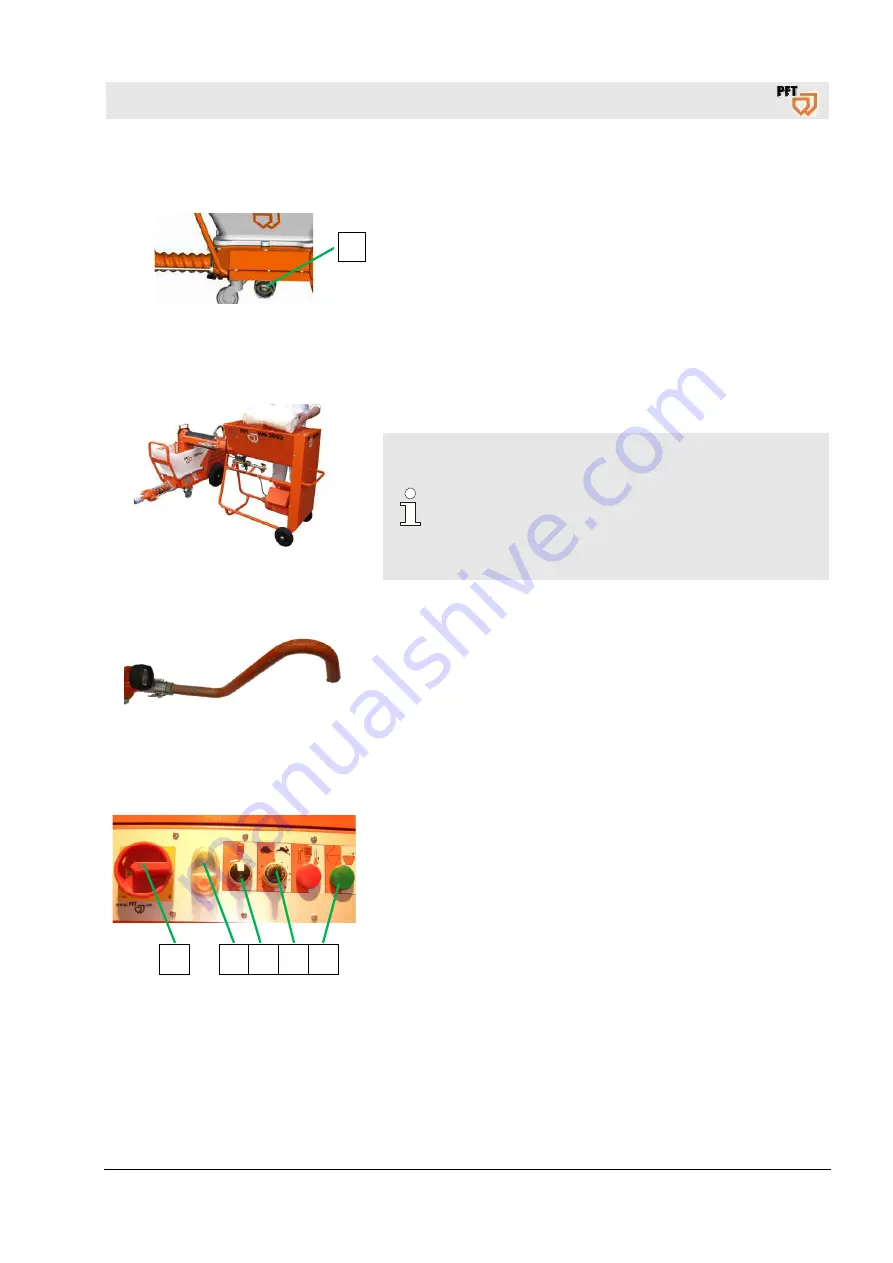

29.1.1 Switching on the SWING L FU

2

4

5

1

3

Fig. 29: Switching on

1. Turn the potentiometer (1) for motor speed / material quantity to

position 5 (readjustment can be made as required)

.

2. Turn the main reversing switch (2) to the “I” position.

3. Green indicator light (3) for control voltage must light.

4. Activate the green illuminated button (4) (control voltage “ON”).

5. Turn the selector switch (5) to the right.

6. Check the mortar consistency.

7. Switch off the SWING L FU, turn the selector switch (5) to

position "Zero" (middle position).

8. Remove and clean the consistency checking tube.

1