PFT Conveying Pump SWING L Overview – Operation – Spare Parts Lists

End of work / Cleaning the mac

46

14/09/2021

41.3 Decouple mortar hose

3

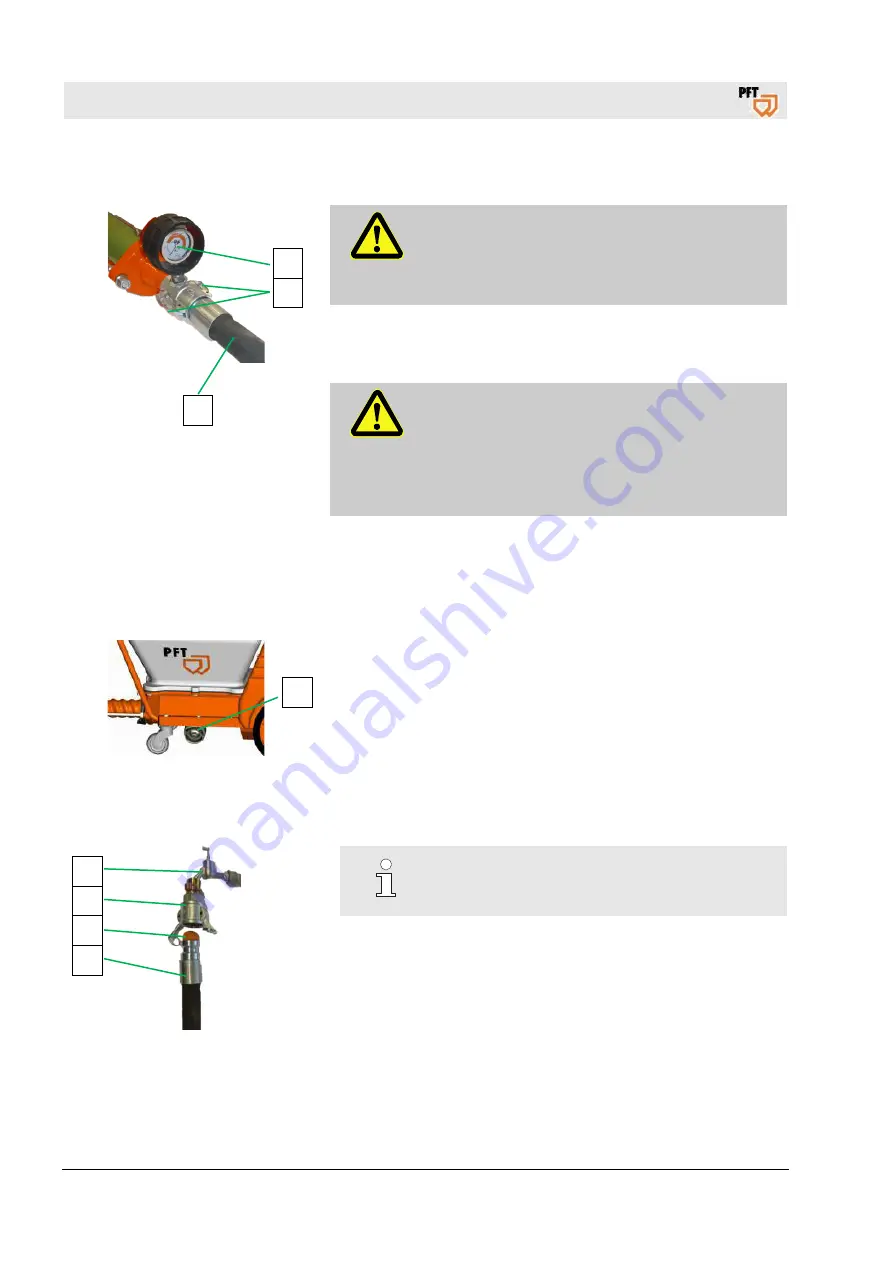

Fig. 65: Mortar pressure to "0" bar

DANGER!

Risk of injury from discharged mortar!

Discharged mortar may lead to injuries to eyes and

face.

Attention, residual pressure.

Open the air cock on the sprayer.

Check at the mortar pressure gauge (1) if the mortar pressure is

at "0 bar".

DANGER!

Overpressure on the machine!

When opening machine parts they can open in an

uncontrolled manner and injure the operator.

Open machine only when the pressure is at "0

bar".

Loosen the cam lever (2) and decouple the mortar hose from the

mortar pressure gauge.

Disconnect the air hose from the sprayer.

41.4 Drain the remaining water

Fig. 66: Open the cleaning cover

Clean residual material from the protective grille and material

hopper with a water jet and pump it down.

Fill the material hopper with water and switch on the machine so

that the pump is rinsed with water.

Remove the cleaning cover (1) and allow the residual water to

drain.

41.5 Mörtelschlauch reinigen

Fig. 67: Clean mortar hose

NOTE!

Mortar hoses and spraying device have to be

cleaned immediately after finishing work.

Connect the cleaner coupling (1) at the water extraction valve

(2).

Press the water saturated sponge ball (3) into the mortar hose

(4).

Connect the mortar hose (4) with the sponge ball to the cleaner

coupling (1).

1

2

1

2

1

3

4