PFT Conveying Pump ZP 3 XL MIX Part 2 Overview – Operation - Spare Parts Lists

Putting the Pump into Operation

Fehler! Formatvorlage nicht definiert.

27

HINT!

Tunnel formation:

Owing to the physical property of the material, it

tends to stick partly on the sidewall of the

container, which can lead to tunnel formation. The

mortar level in the material container should not be

higher than is reasonably required.

9.6 Spray Devices and Nozzles

Spray Devices and Nozzles

Larger nozzles yield slighter throw velocity and hence less rebound.

Smaller nozzles yield better atomisation. It is important that the

distance between air-nozzle pipe and nozzle opening corresponds to

the diameter of the nozzle.

9.7 Applying the Wall Mortar

Fig.: 35 Remote control

HINT!

When working without air (e.g. when pumping wall

mortar) then the machine is turned On and Off over

a 42V-remote controlled clutch. To do this, the

dummy plug of the attachment coupling must be

removed and the control connector of the remote

control connected.

9.8 Interruption or End of Work

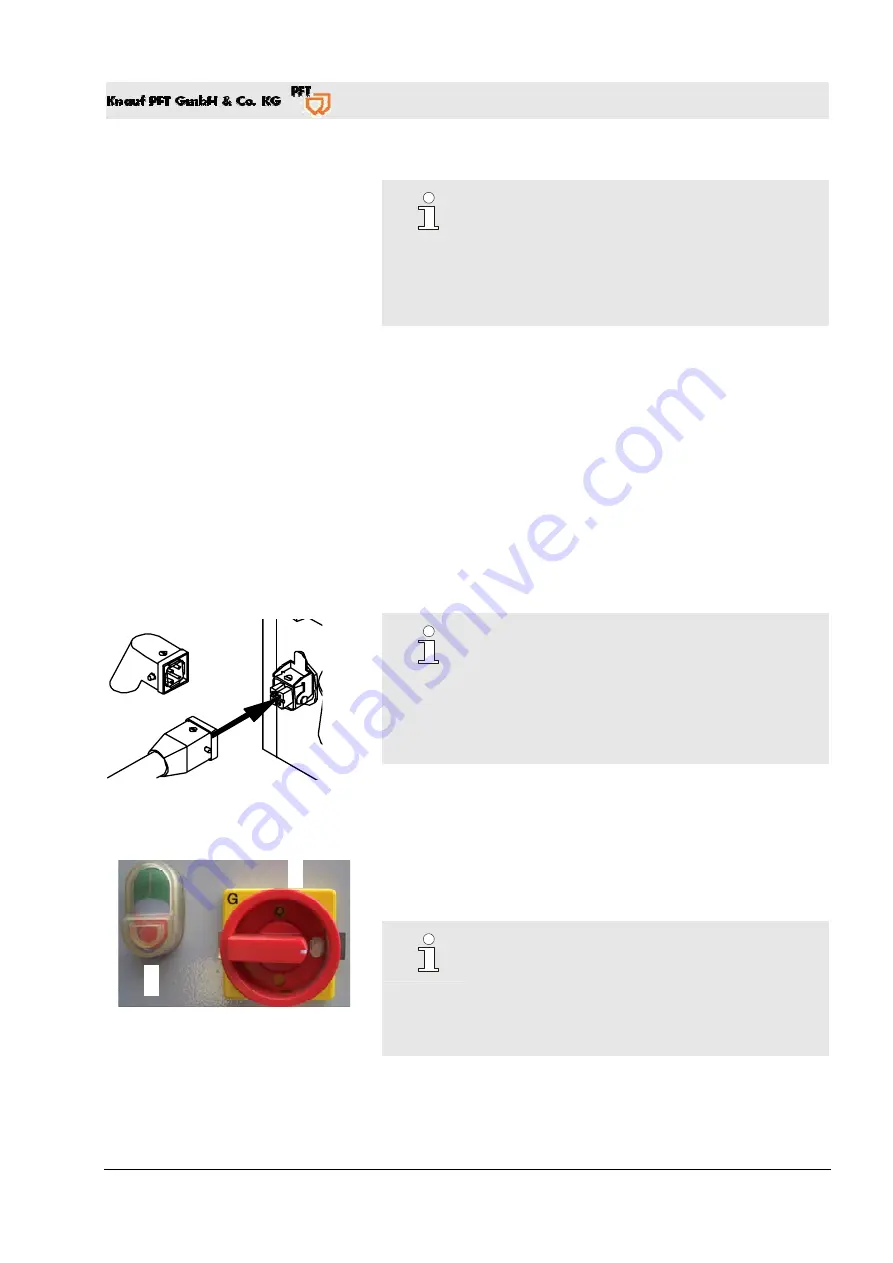

Fig. 36: Switching off

The machine can be turned off via the air cock on the spray device,

via the press button (1) or via the main switch (2).

HINT!

As regards the pauses, the guidelines specified by

the material manufacturer must be observed.

Prior to longer period of interruption, it is appropriate

to clean the pump.

See “Measures at the end of work and cleaning.”

1

2