PFT Conveying Pump ZP 3 XL MIX Part 2 Overview – Operation - Spare Parts Lists

Troubleshooting Tasks

Fehler! Formatvorlage nicht definiert.

31

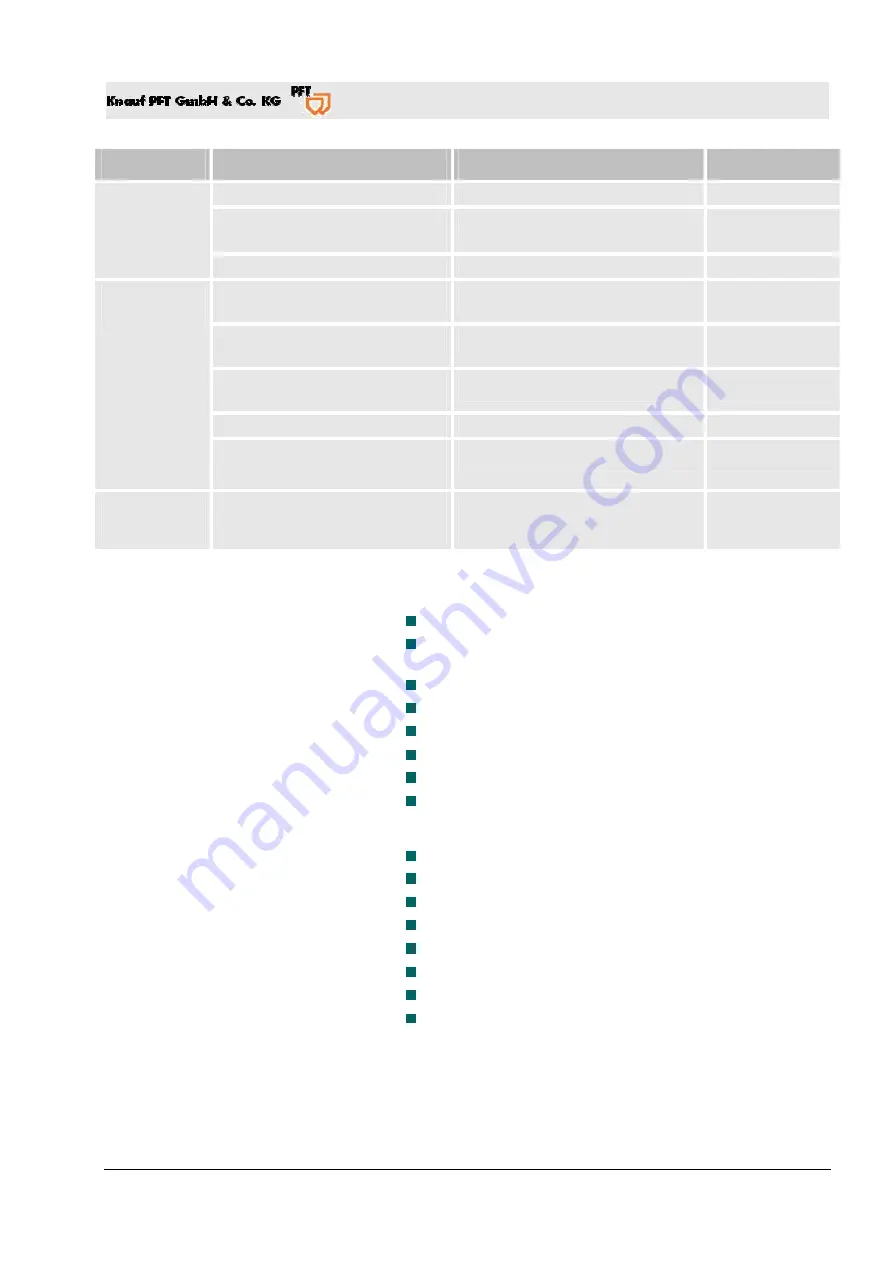

Fault

Possible cause

Fault elimination

Elimination by

Rotor worn out or defective

Replace the rotor

Service fitter

Stator worn out or tensioning clip

too loose

Replace the stator or tighten the

tensioning clip

Service fitter

Non-original PFT spare parts

Use original PFT- spare parts

Service fitter

Main reversal switch not turned on Activate the main switch

Operator

Drum mixer not turned on

Turning on the drum mixer

Operator

Extension cable between switch

cabinet and mixer is missing

Attach the extension cable

Operator

Mixer motor defective

Replace mixer motor

Service fitter

Drum mixer

does not start

Foreign object between gear rim

and drive pinion

Remove foreign object

Operator

Indicator light

is red, fault is

lighted

Overload due to blocked pump

with dried material

Let the machine run backwards,

remove and clean pump

Operator

10.6 Signs for Hose Blockage:

Task done by operator:

Blockage can occur inside the pressure flange or inside

material hoses

Signs for this are:

Rapidly increasing pump pressure

Blocking of pump,

Heavy or blocked pump motor

Expansion and rotation of material hose

No material exit at hose end

10.7 Possible Causes:

Severely worn out material hoses

Poorly lubricated material hoses

Rest water in the material hose,

Clogging of the pressure flange,

Strong narrowing of the coupling,

Kink in material hose,

Leakage on the couplings,

Poorly pumping capable and segregated materials