NewFEIMAS

Refer to Revision Record on page 2.

T.Anzai

Nov. 20, 2008

K.Okada

Rev

04

03

PAGE

45

/

138

PFU LIMITED

P1PA03334-B30X/6

Refer to Revision Record on page 2.

T.Anzai

July 7, 2008

K.Okada

Refer to Revision Record on page 2.

K.Okada

K.Okada

DESCRIPTION

CHECK

DATE

T.Anzai

APPR.

K.Okada

K.Okada

Aug.19, 2005

DESIG

N

DESIG

.

CUST.

I.Fujioka

I.Fujioka

T.Anzai

CHECK

fi-5530C/fi-5530C2

IMAGE SCANNER

MAINTENANCE MANUAL

APPR.

TITLE

DRAW.

No.

Feb.23, 2007

05

Section 3-2-2

3-2-2. Alarms

Alarms require the maintenance conducted by an authorized service person. The following table shows the display and

detection algorithm for alarms. The alarms are displayed on a PC screen and/or on the operator panel (Function No. Display).

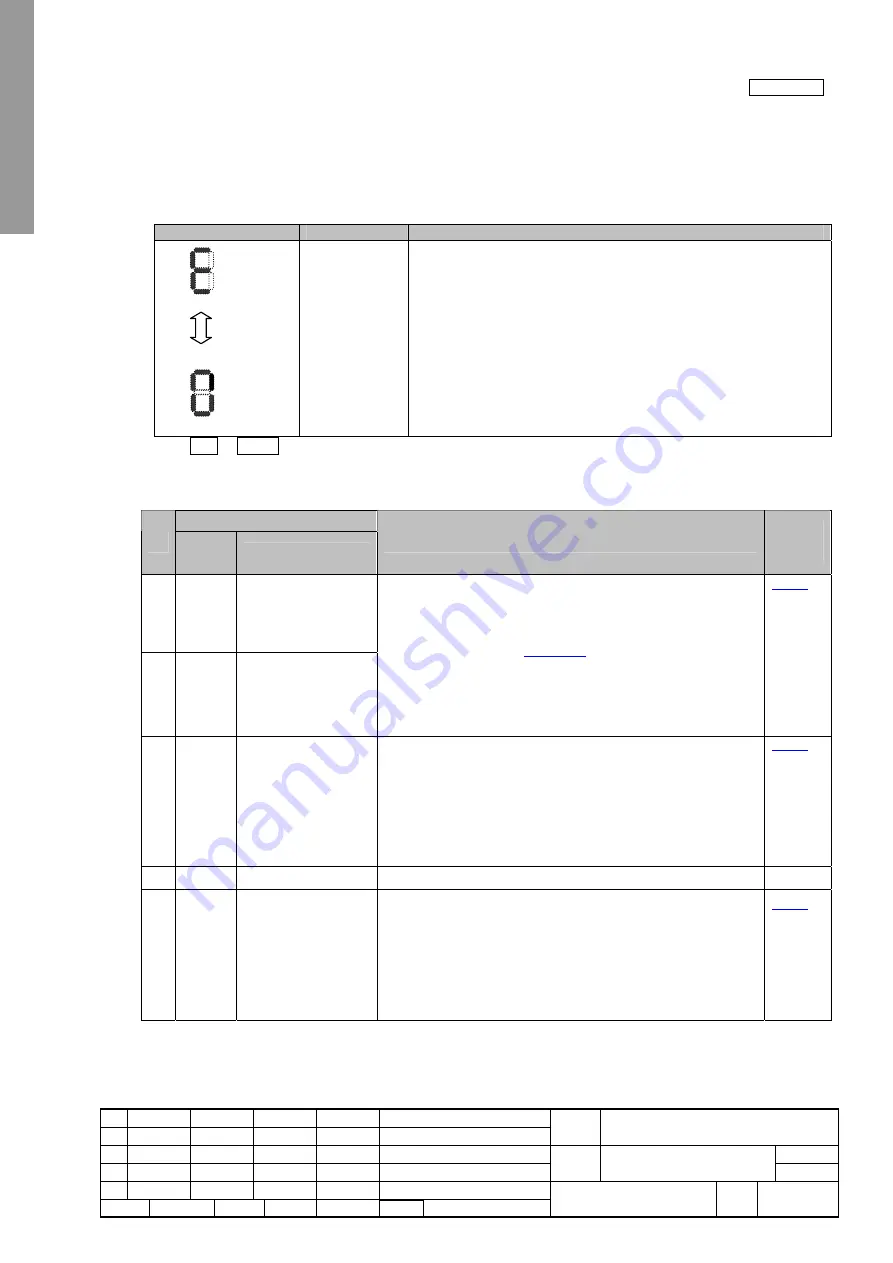

(1) Alarm displayed sequence

When an alarm occurs, the scanner displays the following on the operator panel:

Function No. Display

Power LED

Description

ON

Displays “E” and one of the alarm number (0 ~ 9, A ~ F) alternately.

The example shown in the left column is the case of alarm “E0”.

The display sequence is:

“E”

“0” ……

The interval of changing the display is approximately 1 second.

When Scan or Send to button is pressed while the alarm is displayed, the scanner returns to the “Ready” display (Function

number display).

(2) Alarms and their detection algorithm

Error display

No.

Scanner

display

TWAIN display

Error occurrence algorithm and action to recover

Related

section

1 E2

“Optical error”

2 E3

“Optical error”

E2: Optical alarm (front)

E3: Optical alarm (back)

This alarm occurs if the gain adjustment of the CCD amplifier does

not succeed at a READ command for the first document, or during

scanning. (Refer to (3) in

Section 2-2

)

Probable causes:

- The optical system or white background is dirty.

- Defective lamp or CCD.

- Connector disconnected

3-3-14

3 E4

“Fuse for ADF motor

blown”

Fuse for ADF motor blown

This alarm occurs immediately after the motor fuse is blown. For

maintenance, the whole unit of the Control PCA needs replacing

because the fuse is soldered to the Control PCA.

Probable cause:

- A bit of metal material dropped on the Control PCA

- Insulating material of motor cable damaged

- Insulation corrupted inside the motor

3-3-15

4 E5

None

(Reserved)

5 E6

(Note1)

None

Operator panel alarm

When replacing the Panel PCA, the EEPROM data shall be moved

to the Control PCA and the information that no data exists on the

Panel PCA is written to the EEPROM of the Panel PCA. If the

scanner detects that there is no EEPROM data in Panel PCA during

initial processing at power-on, this alarm occurs.

Probable causes:

EEPROM data is not restored to Panel PCA

3-3-17