RFG-14M Polidek OG p.4

2.

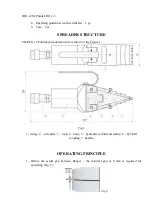

Introduce the wedge head in the gap between flanges until the vertical side of the stop

interacts the flange outer surface (Fig. 3a).

(Fig.3а)

Make sure that the whole step surface is used.

We strongly recommend to use two tools for spreading the gap between flanges that should

be mounted at an angle of 180 degrees to each other (Fig.3b)

Fig.3b

3.

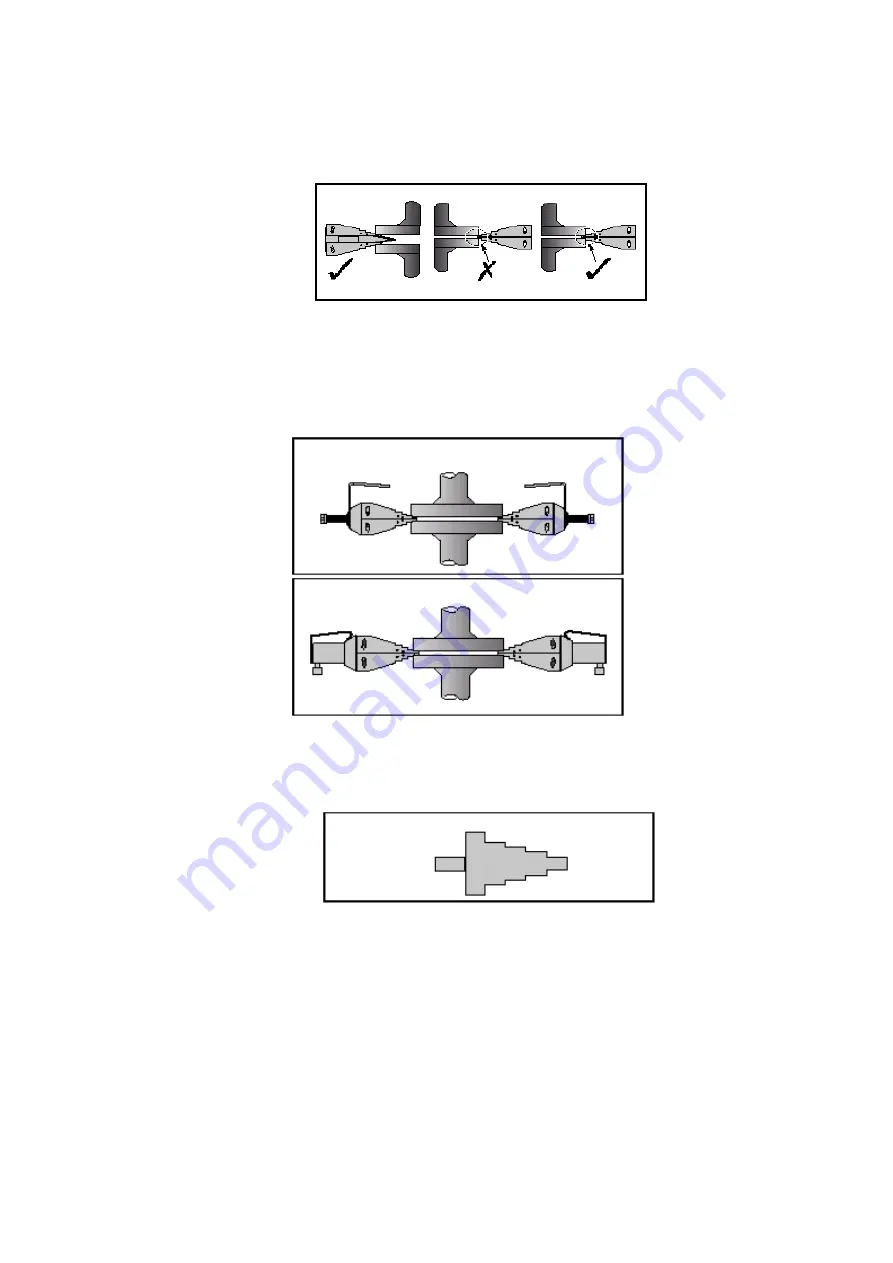

Introduce a safety unit into the gap and shift load on it after spreading flanges to desired

depth or the maximal spreading value for the given step block (Fig. 4).

Fig.4

4.

For further spreading of flanges introduce the wedge head into the gap between flanges and

use the next step of the wedge head.